Various technological innovations of the 20th century realized affluent consumption-oriented societies. Meanwhile, it accelerated wasteful uses of resource and environmental destructions which even became threats to the continuation of life. The 21st century is the “Century of the environment.” It is our mission to use all our energy to solve environmental problems, restore beautiful nature, and leave it to the next generations.

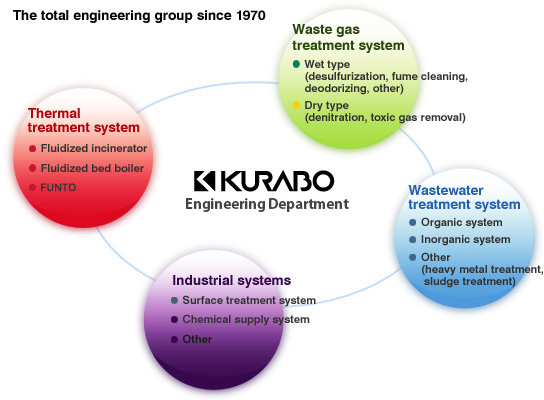

KURABO has been manufacturing products under the Human-Friendly Concept, which takes into account people, the earth, and a healthy environment based on the perspectives of both companies and users since the early phases. The personnel of the Engineering Department have constantly commercialized various treatment systems, such as ones for factory waste gas, wastewater, and industrial waste based on experiments and tests in our own factories. We also have many product lineups including concentration control systems for various chemicals in factory manufacturing lines, FA-related products such as automatic conveyance systems, and blast treatment systems for shipbuilding and bridge construction. With these products, we offer system designs, manufacturing, and constructions that meet the needs of our customers.

In addition, the specialized maintenance division has full knowledge of the characteristics of each product and offers after-purchase customers, including maintenance and inspections after delivery. As the total engineering group, Kurabo Engineering Department is making daily efforts to establish the optimal environmental system. Kurabo Engineering provides support for the problems around you. Please bring your concerns to us.

The Engineering Department's business activities, which are founded on Kurabo's philosophy of "contributing to a better future through the creation of new value," resonate with the SDGs.

- Wet type waste gas treatment system

- Dry type waste gas treatment system

- Waste water treatment system

As the enactment of the Air Pollution Control Act in 1968, flue gas desulfurization systems began to be installed on smoke emission systems in Japan. Meanwhile, Kurabo started our own development before other companies and installed the first KBCA flue gas desulfurization system in our own factory. And,we have the leading results in Japan. We developed elementary technologies for not only desulfurization systems but also removal of acid toxic gas from various sources, for example,wet type waste gas treatment system for garbage incinerators. And, we applied the technologies for wet gas treatment to deodorization and dust removal.

The KBCA flue gas desulfurization system developed for our own factories was highly evaluated by many parties for its desulfurization efficiency, load-following capacity, and ease of operation and resulted in sales to outside customers. The system is now one of the best-selling products in the industry.

- 1.Optimal processes can be selected based on types of absorbents used in the system.

- 1) Magnesium hydrate method

- 2) Caustic soda method

- 3)Ammonium sulfate recovery method

- 4)Wastewater neutralization method

- 2.All components have simple structures, and the processes are automatically controlled. Therefore, operation and management are easy and highly safe.

This is a toxic gas removal system for urban waste incinerators, which is an advanced version of the KBCA flue gas desulfurization system. With the extremely efficient removal of acid gases, such as hydrogen chloride and sulfuric oxide, it satisfies demands in large cities that dry treatment systems alone cannot treat.

- 1.It can efficiently remove heavy metals including mercury by adding a chelating agent.

- 2.It is equipped with a dehumidifying function, and it can prevent the generation of white smoke through the combined use of a gas reheater.

This is a deodorizing system that removes odor-causing components from gas inside an absorption tower. It is capable of preventing high-level odors by combining with the oxidation function using an oxidizer and solid catalysts.

- 1.It selects the optimal absorbents and fillers based on the odor-causing components of the materials to be treated and delivers highly stable deodorizing effects.

- 2.The use of special oxidizing agents (Crandall M) and stationary special agents enables more advanced odor removal at low cost.

- 3.Wet deodorizing systems in addition to wet types are also available. We suggest optimal treatment methods to suit the purposes and conditions of use.

This is a scrubber-type dust remover that utilizes the elemental technology of the KBCA flue gas desulfurization system.

- 1.This system enables stable dust removal ratio through the proper selection and allocation of spray nozzles and the optimal setup of the liquid gas ratio and pressure drop under load.

- 2. We offer total engineering including electronic dust collectors.

Environmental pollution caused by dioxins became the focus of attention, and new guidelines are presented due to revisions of the Implementation Ordinance for Waste Management and Public Cleansing Act in Japan. Since then,dry type gas treatment systems have become a mainstream of waste gas treatment systems. This is composed by filter for removal of acid gas and dioxins,and denitration system removal of Nox and also dioxin. Kurabo, which had many records of the operation of wet type waste gas treatment systems, quickly responded to this trend ahead of other companies.

This is a denitration system based on the contact reduction method, which uses ammonia or ammonia solution as a reducer and breaks down NOx into nontoxic N2 and H2O using the effect of a high-performance titanium oxide immobilized bed honeycomb catalyst.

- 1.The catalyst layer uses the cartridge (unit) method, which allows easy removal and insertion. Properly designing the size and quantity of the unit delivers a stable denitration ratio regardless of the amount of gas to be treated.

- 2.Proper reducer, which suits the conditions of use, is selected from liquid ammonia, ammonia solution, and urea solution to create the optimal supply system.

- 3.The proper reducer control method, which responds to load fluctuations, and our unique mixer restricts ammonia leaks.

- 4.We propose a total system, including facilities, when an acid gas removal system and a dust remove are required for the preparation stage and post-treatment stage.

- 5.Dioxin decomposition systems that use catalysts are also available for dioxin treatment.

This is a removal system that works on acid gas components and dioxins using the bag filter method, which complies with the new guidelines. It removes toxic gases through solid-gas reactions on the surface of a filter cloth by blowing powder neutralizer, such as slaked lime or powdered activate carbon, into the waste gas stack.

- 1.The all-dry system does not require a wastewater treatment process.

- 2.We can make proposals for individual systems as well as entire systems covering the cooling tower, bag filter, chemical injection system, and flue gas denitration system.

- 3.The use of a special reaction auxiliary agent improves reaction efficiency, restricts clogging of the filter cloth, and improves the release efficiency of fly ash.

For the various water treatment needs of gavage incinerators of the public facilities and industries. KURABO builds optimal water treatment systems by combining methods that we developed in our factories for biological treatment, pressure floatation treatment, filtration and membrane treatment, decolorization treatment, and heavy metal treatment. For improving the performance of installed facilities, KURABO proposes systems to achieve the targeted water quality while effectively using already available systems with such tools as bio-actor biological treatment in response to the requests of our customers.

- 1.Builds optimal water treatment systems not only by biological treatment but also by combining physical and chemical treatments.

- 2.Suggests simple systems that suit components to be treated such as persistent substances and decolorization of wastewater.

- 3.Reduces the burden of operation management and running cost.

- ・Food factories ・Shochu breweries ・Other factories of organic wastewater from factories

- ・Waste treatment facilities ・Paper mills ・Chemical factories

・Semiconductor factories

A fluidized incinerator uses silica sand as the heating medium and maintains a fluid state.Therefore it can incinerate wastes instantly and completely when inserting them into the heated silica sand. In response to diversified needs, the combined incineration system, the unique development of KURABO, produces optimal combustion conditions by combinig high moisture content waste and high heat value waste.

- 1.Highly efficient, because it is capable of quick incineration with low air ratio, and it enables a reduction in the size of equipment in the downstream processes.

- 2.Reduces maintenance costs because of the simple internal structure with no movable parts.

- 3.Reduces the generation of NOx, CO, and unburnt components because of nearly uniform combustion inside a furnace, and wastes are quickly and completely incinerated.

- 4.Possible to burn multiple materials with different properties at the same time.

- ・Sewage ・Screen residue ・Grit ・Raw sludge ・Industrial wastewater sludge

- ・Sludge with waste oil ・Waste oil ・Garbage ・Food residue ・Waste egg ・Waste plastic

- ・Wood waste ・Waste tire chips, etc.

This is a thermal recycling system that evolved from fluidized incinerators. It uses biomass fuels including wood chips, tire chips, waste plastics, and sludge, and recovers their energy as steam or heated air. It can also generate electricity when combined with a steam turbine.

- 1.It has higher thermal efficiency because the fluidzed bed system uniformly and instantly burns wood chips and sludge-style materials.

- 2.Possible to burn multiple materials with different properties at the same time.

The Tokushima Biomass Power Plant, which began operation in July 2016, combines steam turbines with our proprietary fluidized bed boiler technology. It uses timber from forest thinning etc. to generate power from wood biomass.

Power Plant Overview

| Generation capacity | : | 6,340kW |

|---|---|---|

| Annual power output | : | About 40 million kWh (equivalent to the annual power usage of around 11,000 typical Japanese homes) |

| Boiler type | : | Fluidized bed |

| Fuel | : | Wood chips such as timber from forest thinning |

This thermal recycling system can repeatedly recycle livestock waste discharged from cattle barns.

With its powerful sterilization and drying capabilities, this system can repeatedly recycle livestock waste (used litter containing livestock excrement and urine) into dry and clean compost.

This system enables significant reductions in the cost of purchasing litter, and in addition to saving effort in manure processing and composting, addresses issues such as bad odors and sanitary management in cattle barns.

- 1.Recycling of used litter through instant sterilization and powerful drying

Our distinctive combustion and waste treatment technology (patent pending) finely grinds livestock waste while instantly sterilizing and drying it at high temperatures. - 2.Automatic operation is easy for just one person to use

In addition to easy operation, maintenance requires little more than daily cleaning, so the system demands no specialized knowledge or skills. - 3.Low-cost, environmentally-friendly RPF fuel

The FUNTO system uses RPF, a solid fuel derived from waste. RPF has an easy-to-handle pellet shape, and is inexpensive. The system makes a further contribution to our environmental conservation initiatives.

This system applies base treatment before painting in shipbuilding, bridge construction, electric power plant, automobiles, and airplanes. KURABO suggests optimal systems, including surface treatment systems, such as abrasive media circulation and automatic recovery system, compact on-vehicle types, and internal and outside treatment systems for structuring pipes, in addition to environmental measures that take into account dust collection and air conditioning in buildings.

- 1.Possible to provide total suggestions from the selection and supply of abrasive media to trial operation and training instructions after delivering the system.

- 2.Offer designs that take into account the easy operation, maintenance, comfortable work environment and energy saving.

- 3.Offers stable quality and quick services with our own designs.

- 4.Uses equipment from Clemco, which has sufficient delivery track records around the world to offer stable systems.

It supports cutting edge industries, such as the semiconductor industry, with high-purity chemical mixing and injection systems, storage and supply system, and design and construction of clean rooms that realize dust-free, sterile clean spaces.

- 1.Provides clean construction of the semiconductor grade using fluorine resin filters and fluorine resin processing technology developed by KURABO.

- 2.Suggests systems that suit customers’ various requests from small (unit) systems and large (bulk supply) systems.

- 3.Realizes high-purity cleansing evaluations in liquid chemical supply systems for the semiconductor industry.

- ・Organic solvents ・Acid chemicals ・Alkaline chemicals ・Remover, etc.

- Engineering Department

- Address14-41, Shimokida-cho, Neyagawa, Osaka 572-0823

- E-maileng_info@kurabo-grp.com