Products

Machine Vision

PET Preform / Bottle Inspection

Inspection of defects such as scratches and air bubbles in PET preform and bottles.

KURABO’s compact inspection system does not require a wide space or major production line changes.

Features

Compact design

KURABO’s compact inspection system does not require a wide space or major production line changes.

Modular design

KURABO can offer five different inspection systems, for mouth top, screw part, support ring, sidewall and bottom of PET performs / bottles.

Establishing an optical system ideal for resolving customer problems

KURABO can provide sophisticated inspection systems employing optical systems and image processing technology that is the most suitable for the customer.

Less excessive exclusion available!

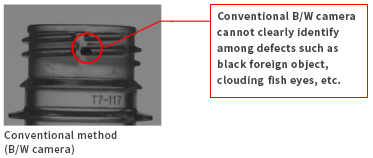

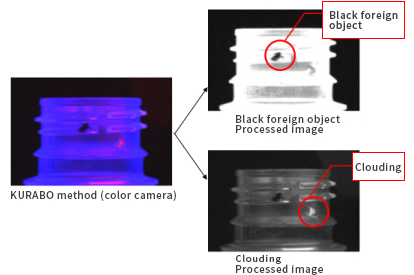

Conventional B/W camera cannot clearly identify defects such as black foreign object, clouding, fish eyes, etc., because of different features.

We provide independent threshold settings for more accurate damage detection based on our distinctive color image resolving technology.

We offer an optical system which contribute to less excessive exclusion.

Specifications

| Item | Details |

| Applicable products | PET performs and empty bottles |

|---|---|

| Processing performance | 1,200bpm |

| Inspection item | scratches, missing parts, black foreign objects, clouding, air bubbles, etc. |

| Inspection location | Mouth top surface, screw part, support ring, sidewall, bottom |