New Era of Pavement Inspection!

In recent years, pavement surveys

have been required to reduce Life Cycle Cost

through efficient inspection methods

and appropriate repairs.

To solve this issue, KURABO supply the compact type road inspection unit PG-4

which is highly accurate and contributes to

reduce inspection & labor costs.

Features of KURABO

Pavement Inspection Unit PG-4

-

01High Speed and

High AccuracyCapture high definition image

with 100km/h highway speed.

No need to close lane. -

02Mount on

General vehiclesNo large modification

of the vehicle body required. -

03Capture both Day

and Night timeCapture at any time without

being affected by sunlight. -

04Improve workability

and fair evaluation

through auto analysisUsing our software, cracks, potholes,

rutting, etc. are automatically extracted.

Results stored as digital along with

geographic data, making it easy to

compare deterioration over time. -

05Abundant options

Additional options such as

2D color line camera, Infrared camera,

and Flatness (IRI) unit can be added

for further analysis.

Effectively measure road surface degradation

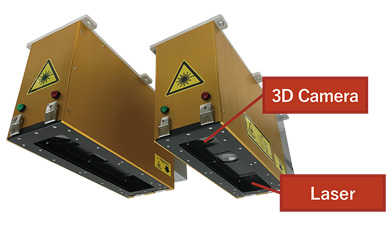

Previously large size vehicle systems were required to do high speed scanning. Therefore, many users were abandoned to purchase them due to budget issues. KURABO use a unique own high-speed and large-capacity image handling technology designed to assemble camera and laser in a compact unit. As a result, we succeed in reducing size and initial investment of the system.

CONTACT

What is KURABO

Pavement Inspection Unit PG-4

-

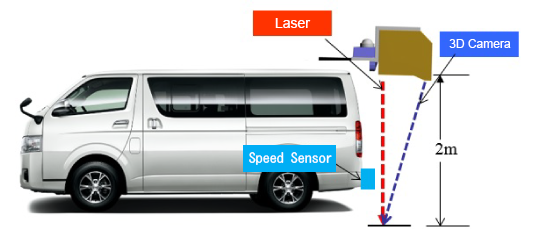

01Mount on General vehicle

A high-definition 3D camera and laser are installed in the compact unit. Since capturing and recording data while driving at high speed up to 100km/h, users don't need to close lanes during inspection, and succeed to reduce on-site work time.

-

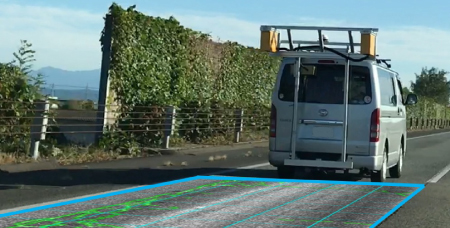

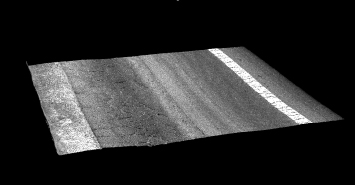

02Capture visual image and

height information using

3D CameraNot only visual image but also height information can be captured. To use this 3D data, various road damages such as the depth of rutting, potholes, cracks, etc. can be captured. Also, inspection can be done both day and night time.

-

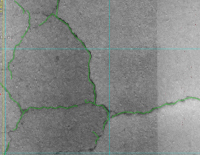

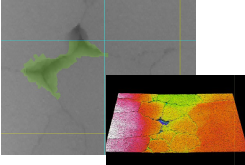

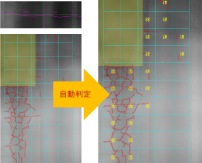

03Reduce analysis time by

automatic extractionFrom 3D height data, our software automatically extracts road damages such as cracks and potholes. Because it is automatically extracted by software, fair and accurate analysis results can be acquired.

-

04User-Friendly Analysis Software

By utilizing various software functions such as batch image input, auto lane mark detection, mesh analysis, auto crack and pothole detection, drawing post process functions, auto rutting CSV output, etc. user can analyze data easily.

-

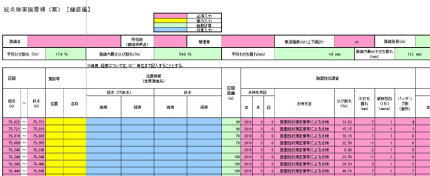

05Output Report

Software automatically judge meshes, calculate crack rate, and output them as a report.

CONTACT

Case Study

Case Studies.

Process Chart

-

Preparation

-

On-site

-

At the office

Simple Pavement inspection!

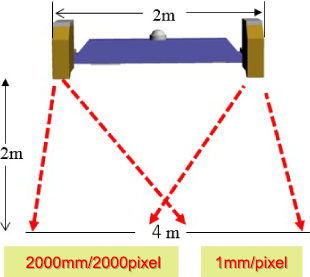

Specification

| Pavement Inspection Unit PG-4 | |

|---|---|

| Image |   |

| 3D camera specification | |

| Survey Speed | Up to 100km/h |

| Transversal Resolution | 1mm/pixel |

| Height Resolution | 0.5mm |

| Longitudinal Resolution | 1mm to 4mm |

| Software Standard Function | |

| Function | Lane mark detection, 2D/3D viewer function, Connect 3D camera data, GPS link, Output arbitrary section, Mesh Process, Auto rut analysis, Auto/manual crack analysis, Auto/manual pothole analysis, crack rate calculation, Post-process drawing tool to draw other defects, Output report with suitable format. Available to handle raw data for evidence of the result. Open source hardware makes user easier to do local maintenance. |