KURABO Railway Tunnel Scanner

TM-270

Feature of KURABO

Railway Tunnel Scanner TM-270

-

point01Compatible with

various shapesFlexible design supports to scan various tunnel shapes such as single track, multitrack, horseshoe-shaped tunnel, circular tunnel, etc.

-

point02Variable speed for

measurementCan be used on trolley up to 20km/h.

-

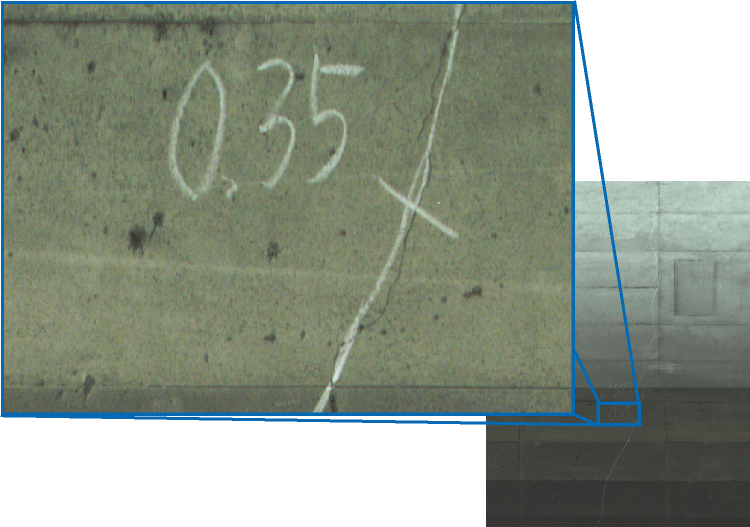

point03Only 5 steps

to assemble!Assemble the unit on site within short time by 1-2 person.

-

point04High resolution

imageHigh definition color line camera and encoder capture high resolution wall image with various speed.

-

point05Excellent

analysis softwareProven KURABO analysis software support to create tunnel deficiency map with accurate cracks length and width information on it.

High speed and law cost tunnel inspection system

A lot of railway tunnel inspection should be done for only 3-4 hours between the last train and the first train. Conventional visual inspections using large high place working vehicles have limited work volume. To use TM-270, user can carry by hand on site and scan tunnel surface with high resolution to detect hair cracks. TM-270 is the inspection system for railway tunnels that greatly reduces labor and efficiency on site.

CONTACT

What is KURABO

Railway Tunnel Scanner TM-270

-

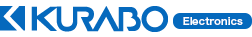

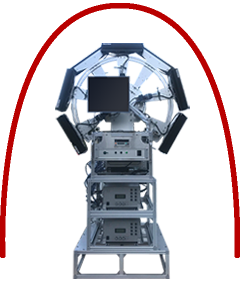

1High Definition

ImagesWith our large-capacity image processing technology, user can obtain clear tunnel wall images from seven high definition color line cameras. Even hair cracks are captured.

-

2Only 5 steps to assemble

By designing the scanner system into a small unit, it is easy to install TM-270 on site with one or two people.

-

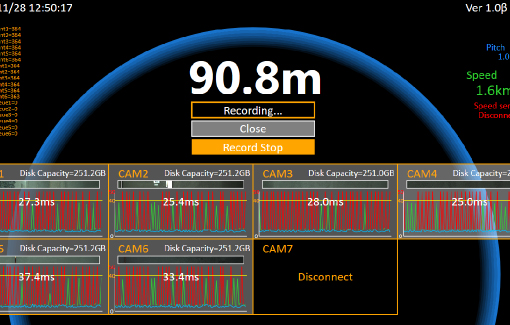

3One click Scan

Usr friendly software supports user to scan tunnel easily on site.

-

4Create Lining Image

AutomaticallyInput tunnel shape, then our software creates tunnel lining surface image automatically.

-

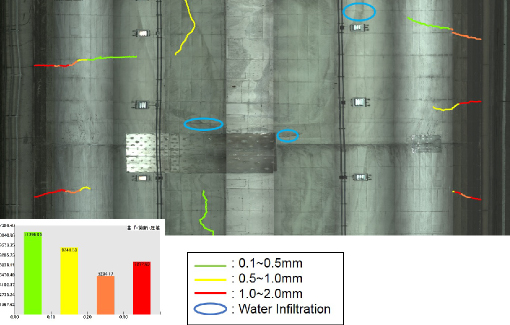

5Analyze images

using our softwareUser can extract cracks and draw other defects such as water leaks to create deficiency map. Then output its analysis result including images, areas, lengths/width of crack, each defect numbers, etc. to image data, CAD(DXF) data, CSV data, etc.

CONTACT

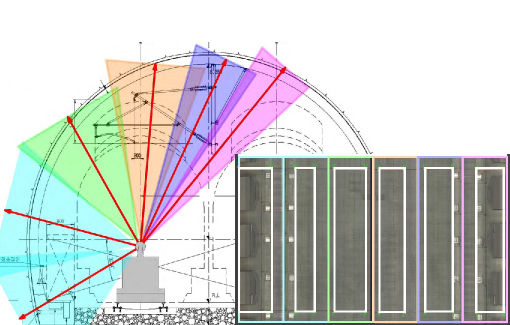

Case Study

TM-270 is available to adjust scanning area depends on tunnel shapes. Therefore, user can create one stitched tunnel image map even it is single track or multi track.

-

Single track

Seven cameras

cover 300 degree.

-

Multi track

Six cameras

cover 180 degree.

Process Chart

-

Preparation

-

On-site

-

At the office

Simple tunnel inspection.

Specification

| Railway Tunnel Scanner TM-270 |

|

|---|---|

| Image |   |

| Imaging device | High resolution color line camera |

| Cameras (300 degree) | 7 (Ul to 8 depend on tunnel shape) |

| Lighting system | LED lighting |

| Transversal resolution | 1mm/pixel |

| Travel direction resolution | 1mm/pixel |

| Survey speed | Up to 20km/h |

| Acquisition | Trigger mode (Encoder) |

| Power | Maximum 1.7kW (Depend on the configuration) |

| Tunnel shape | Maximum tunnel height by approx. 7.5m |

System Configuration

| Unit | Items | Qty |

|---|---|---|

| Inspection Unit | Line camera | 7 |

| LED lighting | 7 | |

| Camera mounting unit | 1 | |

| Control Unit | Capturing PC | 2 |

| Distance display counter | 1 | |

| Encoder | 1 | |

| HUB | 1 | |

| Power supply for LED lighting | 2 | |

| Sync Box | 1 | |

| Monitor | 1 | |

| Mouse, Keyboard | 1 |