ABOUT

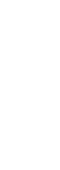

KURATTICE ECO is used in a broad range of applications, from high-rise buildings to exteriors.

KURATTICE ECO uses a recycled wood-plastic composite to coat aluminum using Kurabo’s unique integral extrusion molding technology which is then sanded to create a natural timber feel. KURATTICE ECO is both lightweight and strong and boasts long-term durability and workability, making it suitable for a broad range of applications, from high-rise buildings to homes and exteriors.

-

Commercial facilities

Total coordination of commercial facilities

Like timber, KURATTICE ECO can be used in a variety of applications such as louvers and benches, and because it can be fabricated to meet individual requirements, it can create spaces with appealing designs.

-

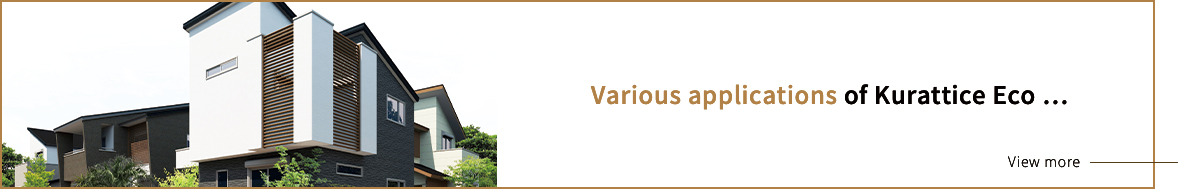

Public facilities

Preserve the scenery of public facilities

With a texture that looks exactly like natural timber, KURATTICE ECO helps to create a rich, natural look.

With excellent durability and weather resistance, there is no need to worry about deterioration, even under severe weather conditions. -

Residential homes and Housing complexes

Appealing designs to showcase your home

Enhance the design of residential homes and housing complexes by incorporating KURATTICE ECO as an exterior feature.

Because it is light, it is also easy to handle, reducing the workload on construction sites.

Utilization image

-

Louvers

-

Benches

-

Fences

CONSTRUCTION EXAMPLE

- All

- Commercial facilities

- Public facilities

- Residential homes and

Housing complexes

-

Kindai University Academic Theatre 1 / louvers

(photo provided by Kindai University)Kindai University Academic Theatre 1 / louvers

(photo provided by Kindai University)

-

Menarco Tower(Philippines)/ louvers

Menarco Tower(Philippines)/ louvers

-

Deck

Deck

-

Curved bench

Curved bench

-

Gatepos

Gatepos

-

Bench(example)

Bench(example)

-

Decorative bench(example)

Decorative bench(example)

-

Fence

Fence

-

Louvers

Louvers

-

Fence

Fence

-

Curved fence

Curved fence

-

Louvers

Louvers

TECHNOLOGIES & FEATURES

KURATTICE ECO is made by the monolithic molding of aluminum and wood powder resin.

It offers both premium design with a natural wood feel, and the strength and long-term durability of aluminum.

KURATTICE ECO can be used for applications that take full advantage of these benefits.

- 01

- 02

- 03

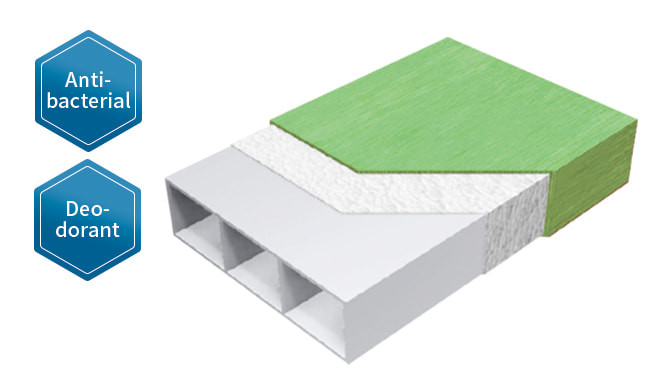

01 Surface (Wood-plastic composite)

Some of the raw materials are environmentally friendly, for example thinned wood, recycled plastic. In addition to wood, other recycled materials can also be used. For example, tea leaves c, and waste from sewing factories.

We also consider the protection of the global environment and the effective use of resources.

02 Bonding agent

The resin surfase and aluminum core are bonded firmly together via an adhesive layer.

This means there is no need to worry about the resin surface peeling in high-humidity outdoor environments or environments with large temperature variation.

03 Aluminum core

Using an aluminum core as the base material, the product is both lightweight and high strength. It won’t warp, bend or distort as it ages, and it can be machined and installed in the same way as aluminum materials.

Wood texture

-

High-strength

KURATTICE ECO boasts the natural feel of timber together with the high-strength of aluminum. This durability makes it suitable for a variety of applications, from homes and exteriors to high-rise buildings.

-

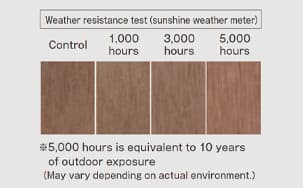

Durability /

weather resistance

The resin surface is firmly bonded with the aluminum core. This means there is no need to worry about the resin surface peeling, cracking, warping or bending in high-humidity environments or environments with large temperature variations.

KURATTICE ECO is resilient against changes in climate and is not as prone to color discoloration as real wood, requiring little maintenance. -

Light weight /

workability

The integrated design, consisting of an aluminum core and resin coating is lightweight. It is easy to handle and can be designed and fabricated for improved workability.

-

Fabrication /

design compatibility

KURATTICE ECO can be bent in the same way as other aluminum materials without losing the natural timber design features of the surface layer.

This makes it suitable for a range of designs, further expanding possible applications.

DEVELOPMENT DESIGN

KURATTICE ECO can be developed and designed to suit customer requirements and product themes. Kurabo can offer proposals that meet a wide range of needs, from residential homes to high-rise properties and exteriors.

- Product requirements & themes

-

-

Large-scale

construction

-

Original

designs

-

Environmentally friendly

& functional

-

- KURATTICE ECO applications

-

-

Can be used for a variety of cross sectional shapes

With its excellent durability, weather resistance and strength, KURATTICE ECO can be used safely in high-rise properties.

KURATTICE ECO can also help to ease the effort required for installation and reduce construction time with proposals based around large, dynamic cross sections and cross-sectional design to improve workabillity.

-

Bending for improved design and fabrication

Using a cross-sectional design approach and variety of fabrication and design methods, such as bending, Kurabo can also propose designs that can only be achieved with KURATTICE ECO. In addition, Kurabo provides total support, from variety of fabrication methods to assembly.

-

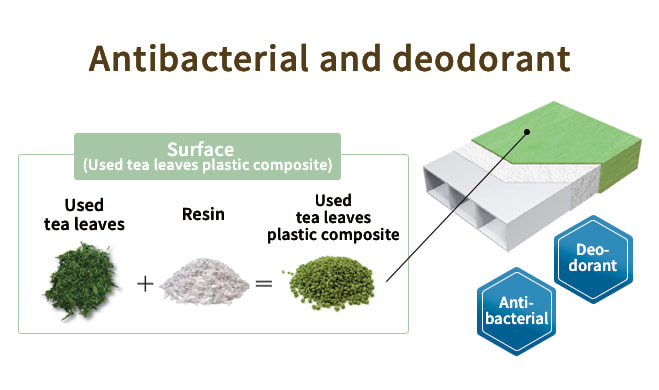

Composites and effective use of recycled materials

Various additional functions can be added to KURATTICE ECO using composite technologies and the selection of resins.

Recycled materials can also be used to provide new value that cannot be found in conventional building materials.

For example, used tea leaves can be used to provide antibacterial properties, and waste from sewing factories can be used as building materials for apparel stores.

-

Custom Order

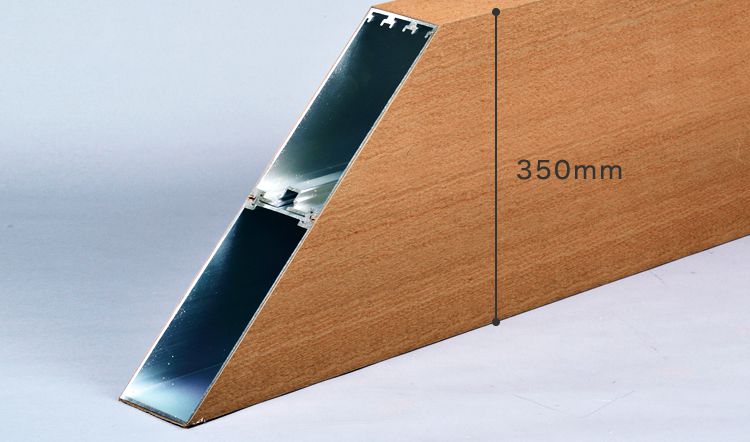

Large cross-sections

Large cross-sections

In general, the maximum fabrication size is less than 250 mm in width and less than 150 mm in height.

However, after the modular design and forming of the product cross-sections, they can be joined and then sanded to achieve a large cross-section.

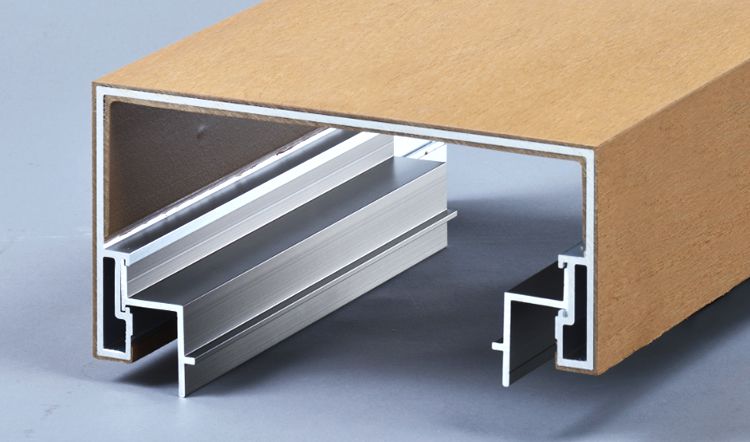

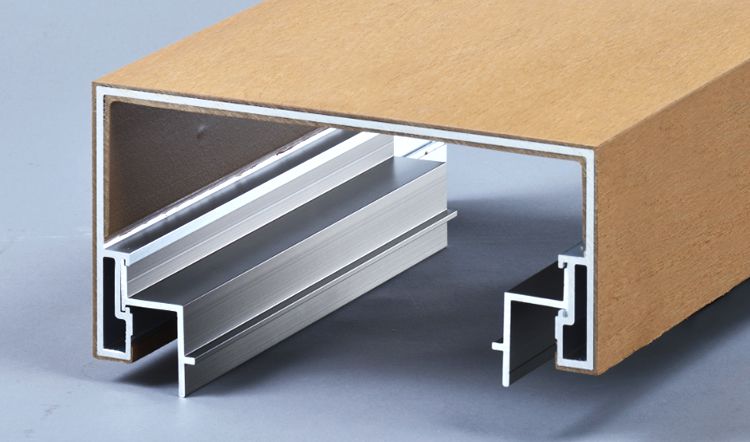

Partial coverage/Metal joints

Partial coverage/Metal joints

KURATTICE ECO is made using partial coverage technology and fusing two differently shaped parts together, a feature of aluminum material.

It can be easily joined with frame joints, and care is taken to ensure mounting screws are not visible.

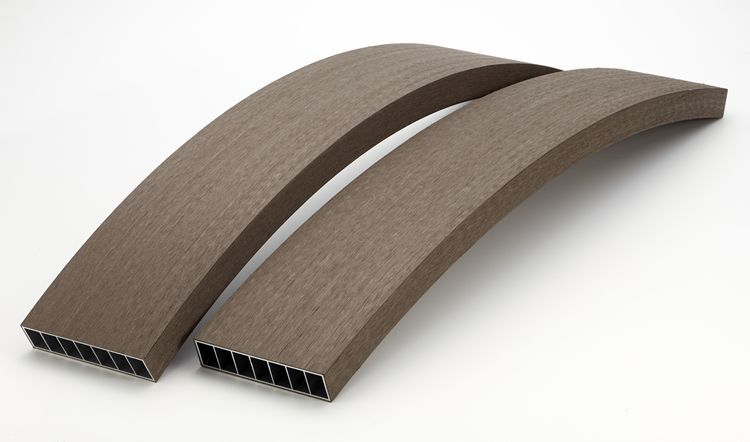

Bending

Bending

Bending is possible while keeping the wood texture. This enables a broad range of designs and uses.

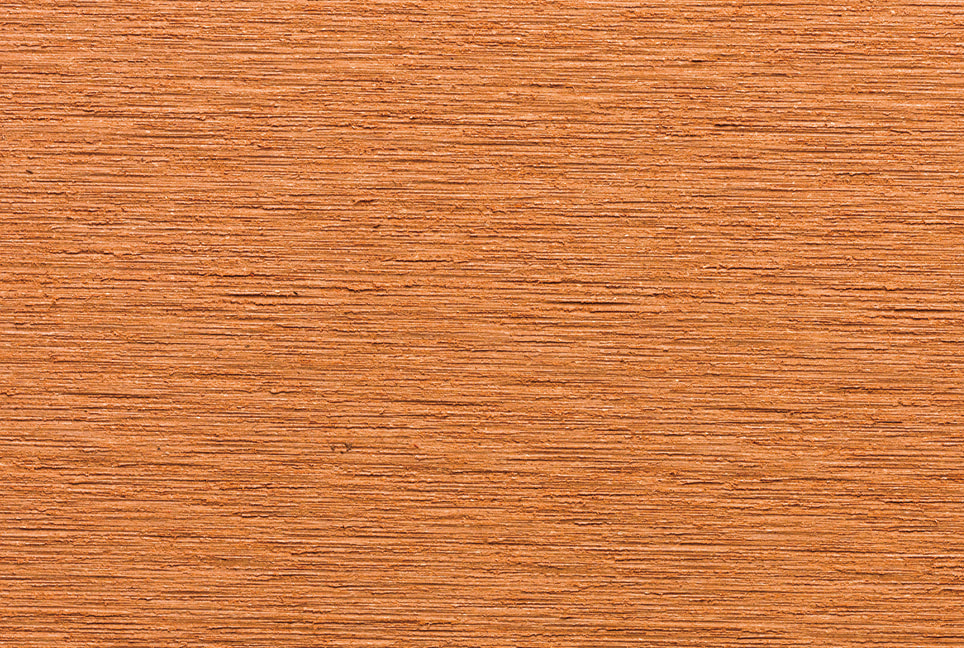

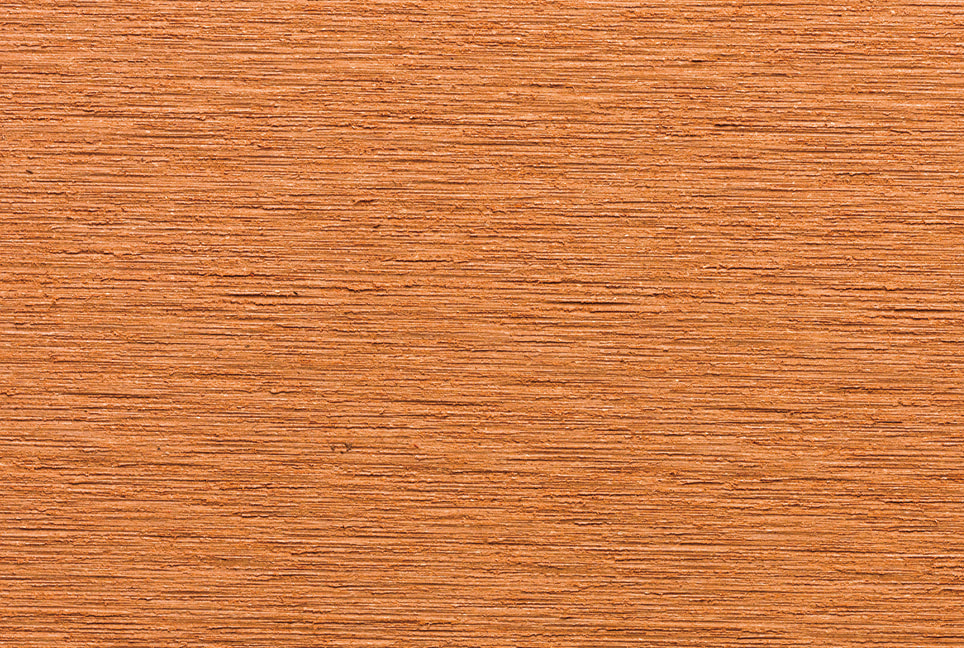

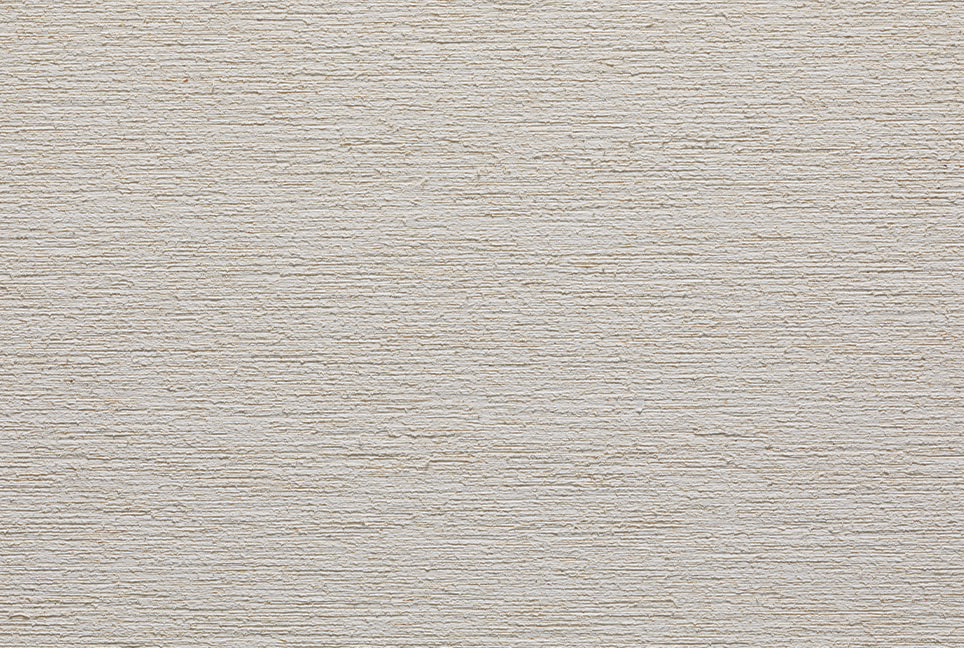

Textures

Textures

In addition to the standard natural timber feel, our surface molding technology allows for a variety of textures. For example, wood grain patterns and stone grain patterns.

Colors

Colors

Not only wood tones, but also a variety of colors are available.

Antibacterial and deodorant

Antibacterial and deodorant

Various additional functions can be added to KURATTICE ECO using composite technologies and the selection of resins. Using used tea leaves with Kurattice eco, can be used to provide antibacterial and deodorant. Suitable for use in hospitals, nursing homes, and public facilities where hygiene is a must. It is also ideal for use in animal-related facilities, sports gyms, and super public baths where odor is a concern.

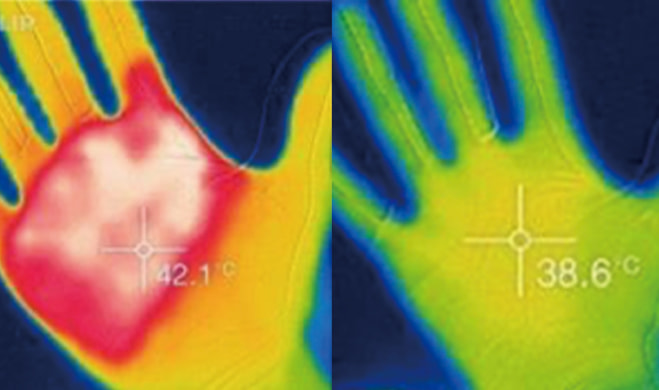

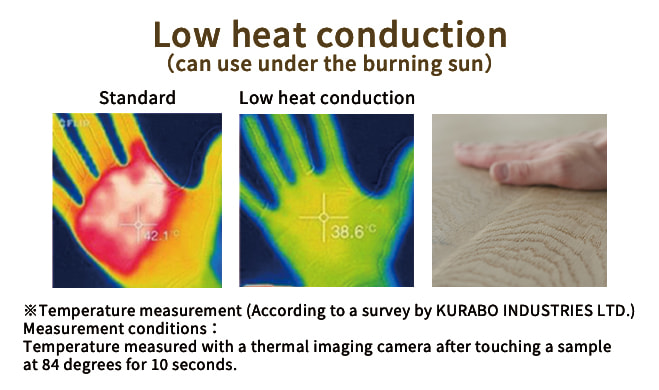

Low heat conduction

(can use under the burning sun)

Low heat conduction

(can use under the burning sun)

Our unique raw material blending and molding technologies have made it possible to achieve the function of "not hot to the touch.

It can be used for applications such as decks, benches, fences, and handrails where hands and feet touch in high temperature environments.

CASE

some examples of proposals and points for adoption.

- Large-scale construction /

Louvers - Public facilities /

Benches

01.Request

The project for the exterior louvers of the Kindai University Academic Theater No. 1 in Osaka Prefecture was characterized by a very high level of design. The use of natural wood as a louver material was considered, but its use was abandoned due to concerns about durability and weather resistance. It is not uncommon for weather resistance and durability to prevent the use of such materials in such large-scale buildings. Therefore, it was decided to consider Kurattice Eco, which has a design comparable to natural wood and is highly durable and weather resistant.

02.Proposal

Kurattice Eco is a material that has the feel of natural wood, but with high durability and weather resistance. It has been used in high-rise construction projects in Southeast Asian countries, where it is hot and humid, so it can be used in any environment.

In addition, because of the high level of design in this theme, the difficulty of construction was an issue. Therefore, we proposed a design that would simplify the on-site construction while maintaining the design

03.Evaluation

The design of the louvers is very similar to the existing natural wood louvers. There is no problem with the weather resistance and durability even after almost five years.

Taking advantage of the freedom of design that only aluminum-plastic composite materials can offer, we created a mechanism that allows easy installation of the louver material and the frame side. As a result, we were able to contribute to reducing the workload on the site, although it was difficult work due to the high location and the high design of the building. In addition, we were able to assist in smooth construction by implementing delivery support in line with the construction process.

- Deciding factor

-

-

01

・Design equivalent to natural wood

・Sufficient weather resistance and durability for outdoor use -

02

・Can be designed for easy attachment to the building frame.

-

03

・Can be designed to accommodate curved building structures with high design quality.

-

01.Request

This is a new project for a wooden bench that can be found in various scenes of our lives, from public facilities to parks. Lack of strength and obsolescence of the design have been the issues, and many alternative materials have been considered. However, there were no satisfactory alternatives.

Therefore, it was decided to use Kurattice Eco, which not only has a woody feel but also has many additional features.

02.Proposal

In addition to the standard straight design, we proposed a design that incorporates curves by taking advantage of the feature of being able to bend while maintaining a wood-like design.

Kurattice Eco has been used as a bench material and decking material for many years, and its strength, durability and weather resistance are not a problem.

03.Evaluation

By incorporating a bending design, the product can be used in a variety of situations, which has led to many adoptions.

We also succeeded in increasing the overall strength and simplifying the design by taking advantage of the features of the composite material, which also led to cost reduction by reducing the number of components.

As a new challenge, we are developing products with functions such as "not hot to the touch" and antibacterial functions by utilizing the unique design and development capabilities of Kurattice Eco.

- Deciding factor

-

-

01

・Can be bent without damaging the wooden design.

(Difficult process for other products) -

02

・Higher strength than conventional products

(Strength unique to aluminum and resin composite materials) -

03

・Design simplification

(Reduced the number of parts by devising a new shape.)

-

PRODUCTS LINEUP

We offer a wide range of products to meet the needs of our customers.

We also offer options and special order services, so please feel free to contact us.

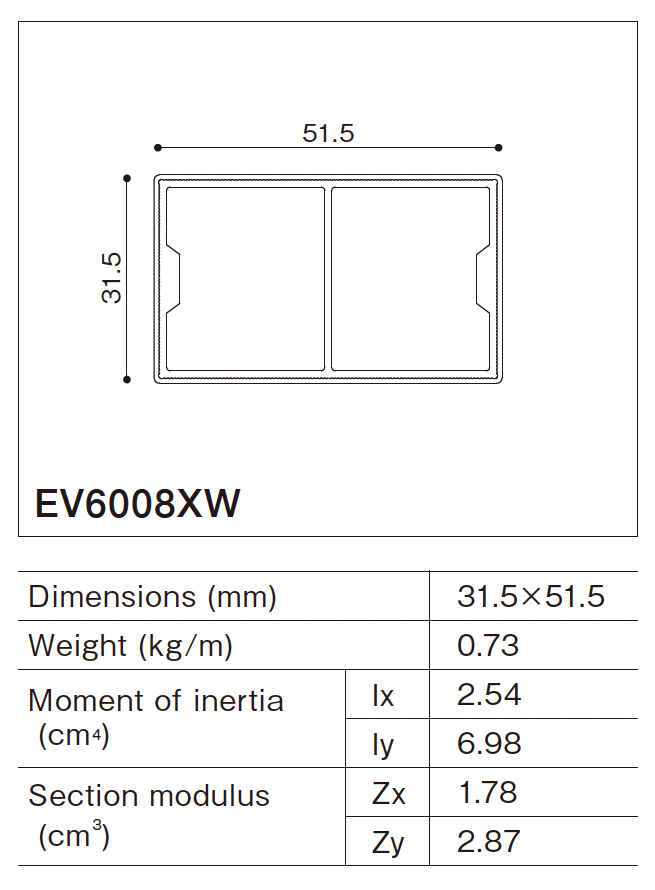

31.5x51.5(mm)

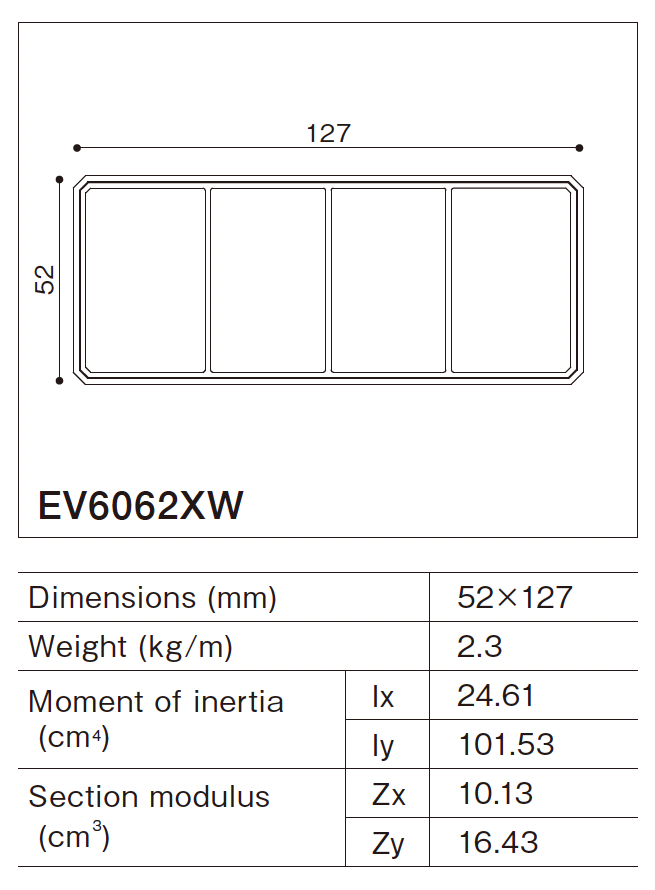

52x127(mm)

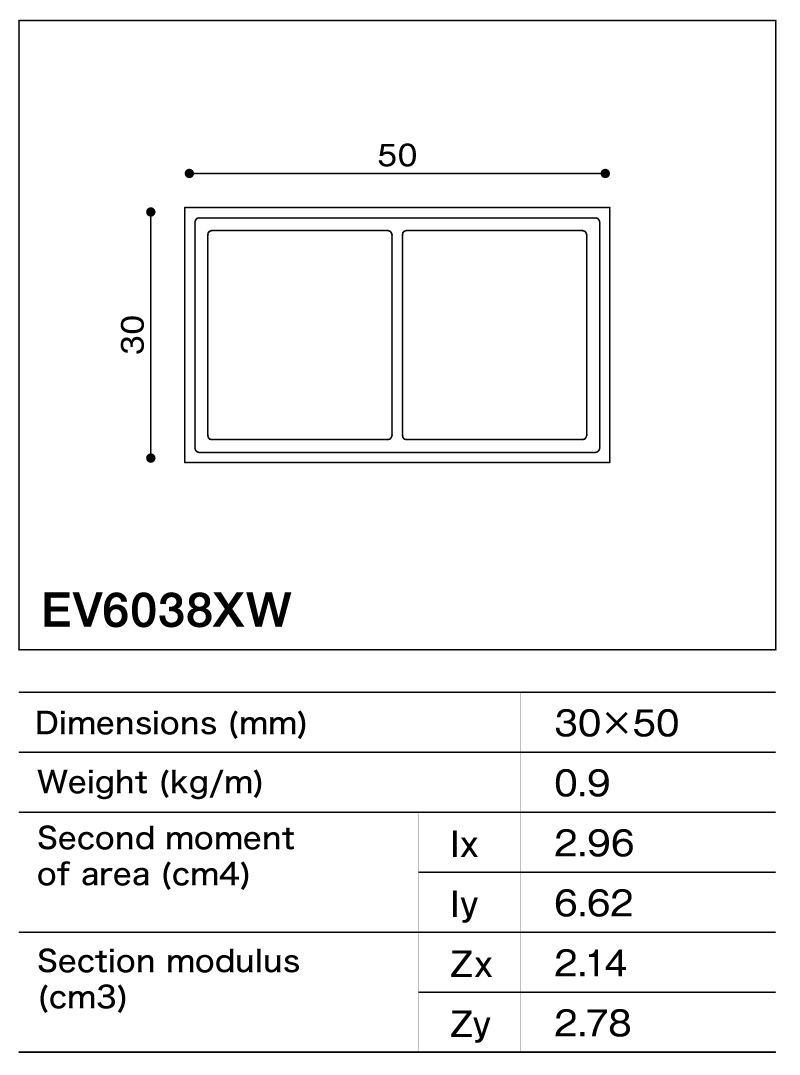

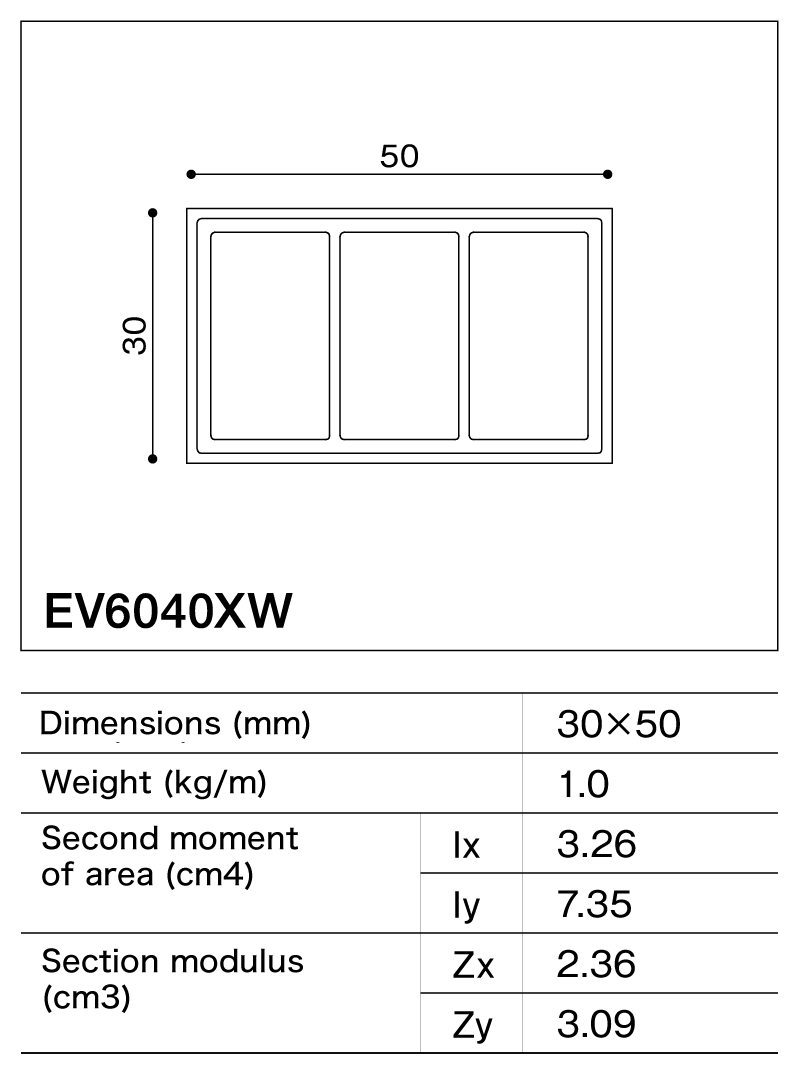

30x50(mm)

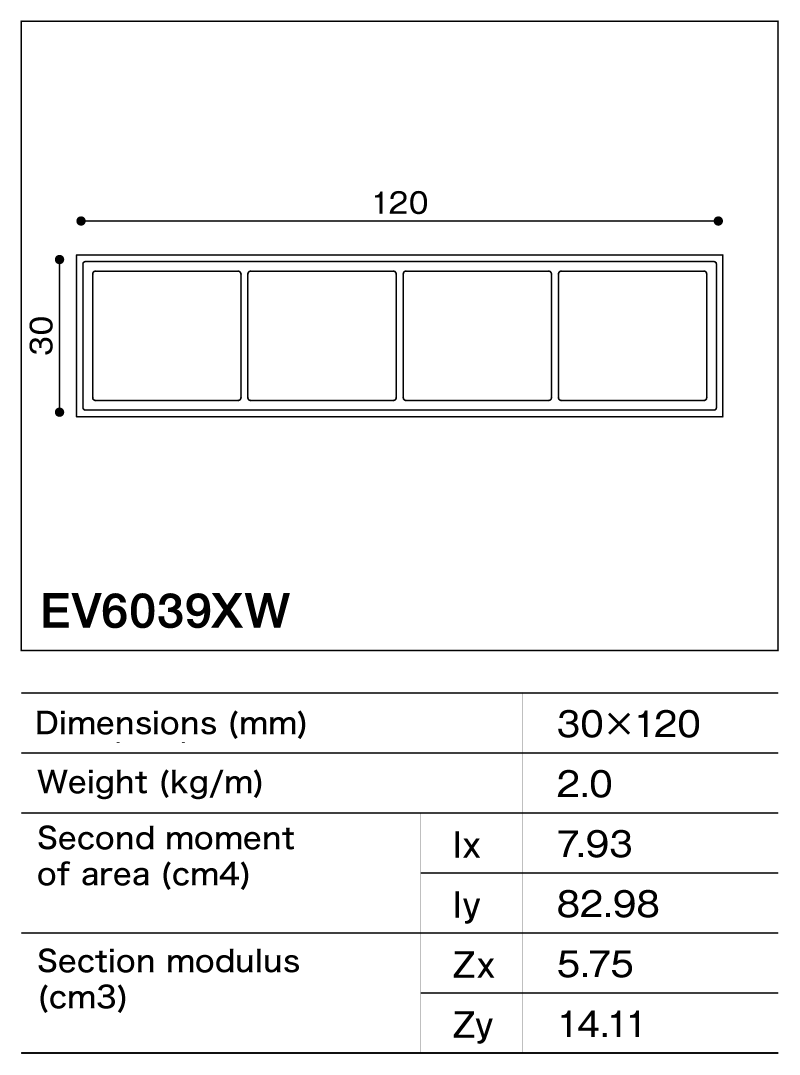

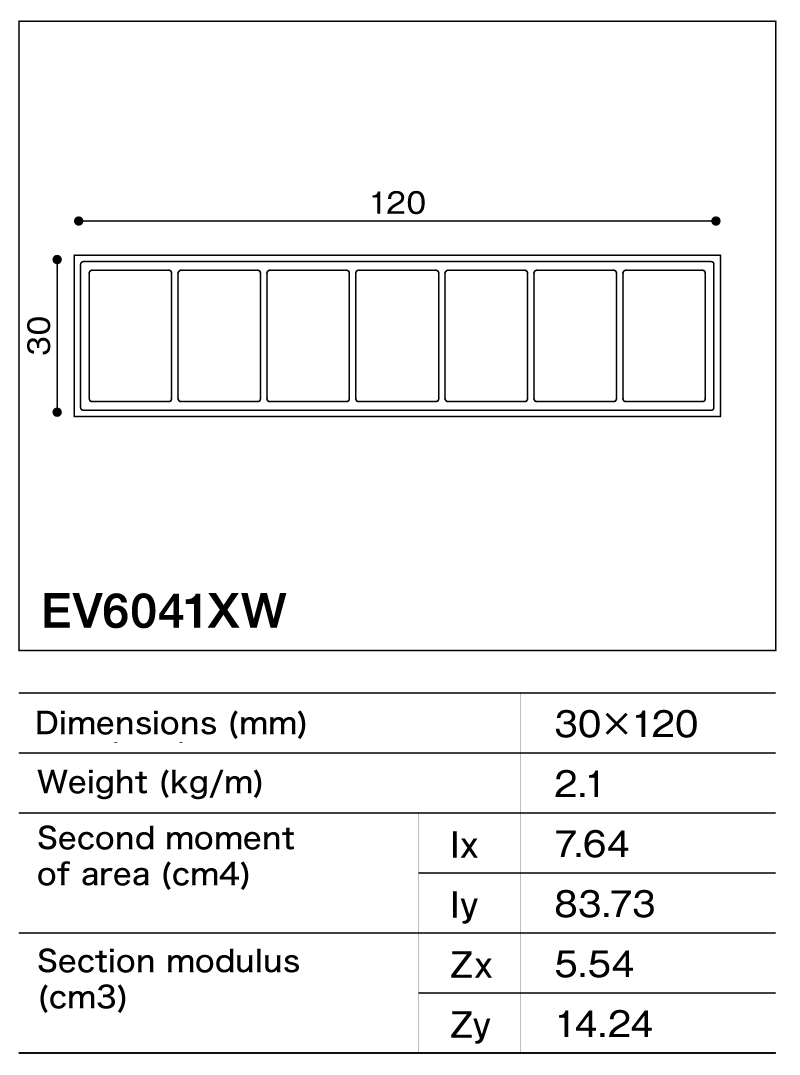

30x120(mm)

30x50(mm)

30x120(mm)

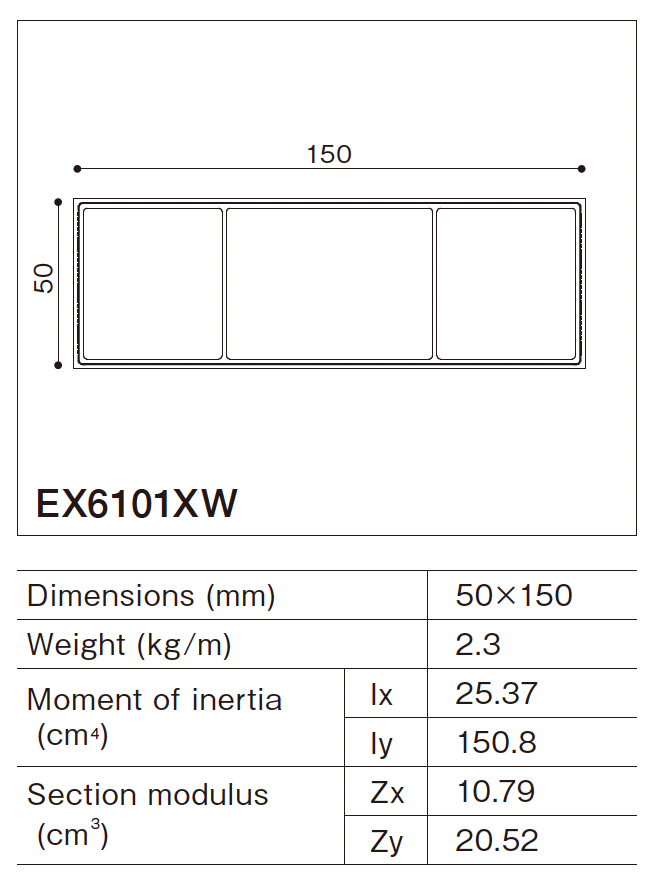

50x150(mm)

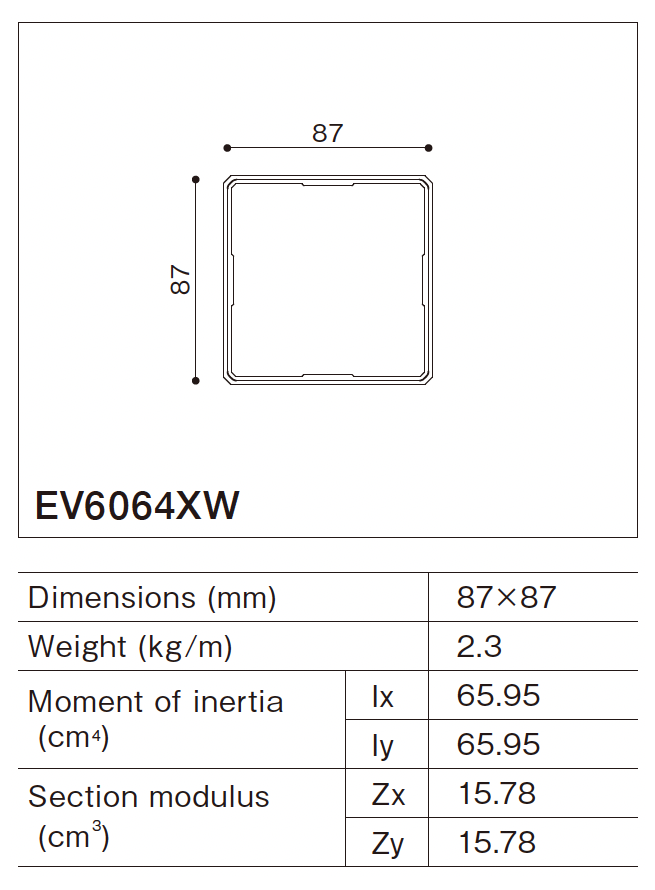

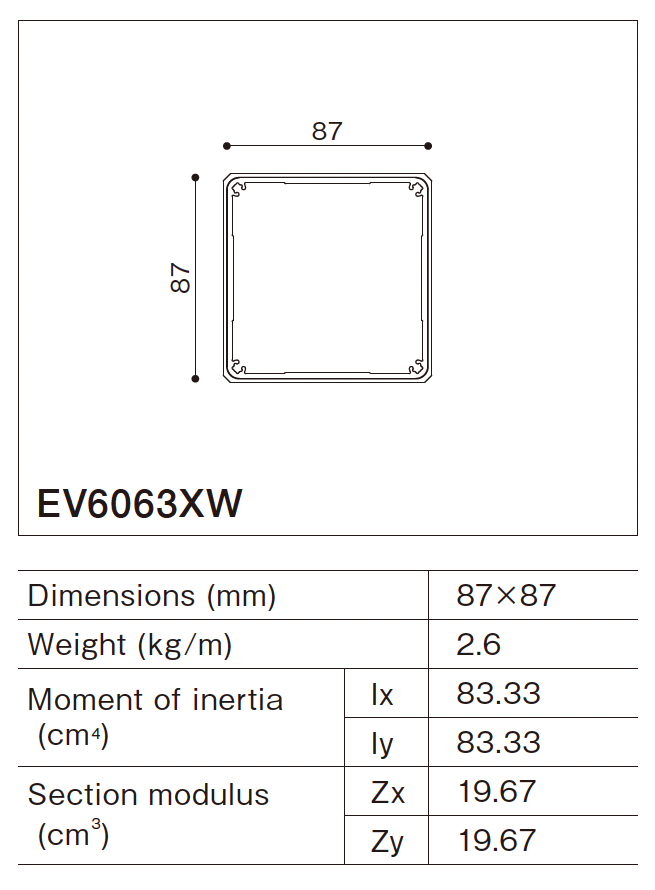

87x87(mm)

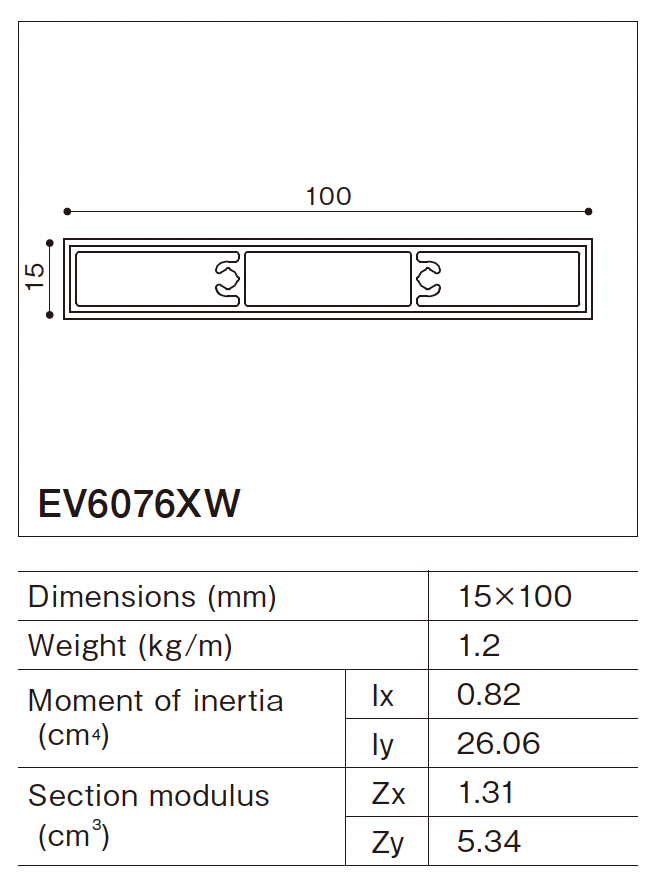

15x100(mm)

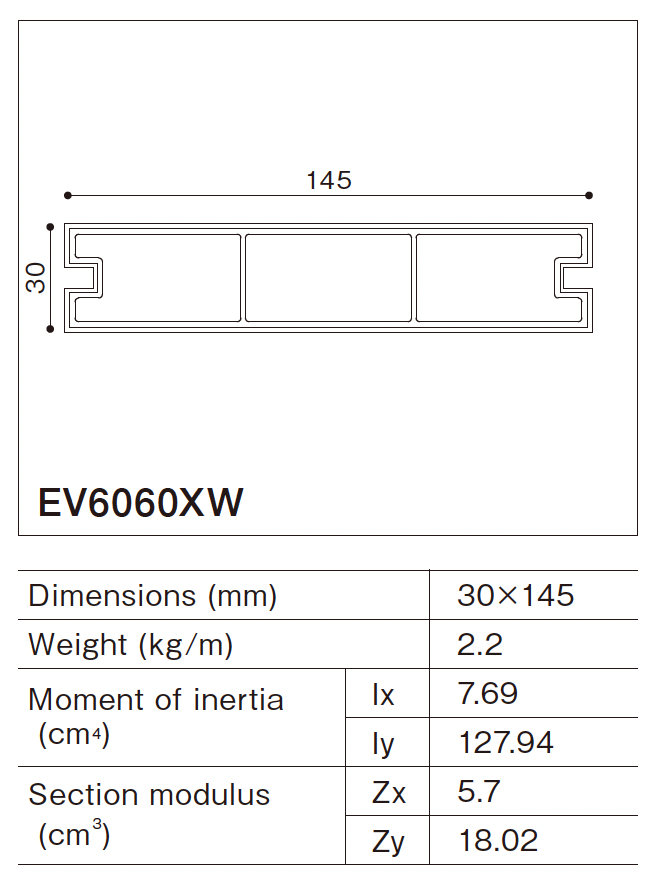

30x145(mm)

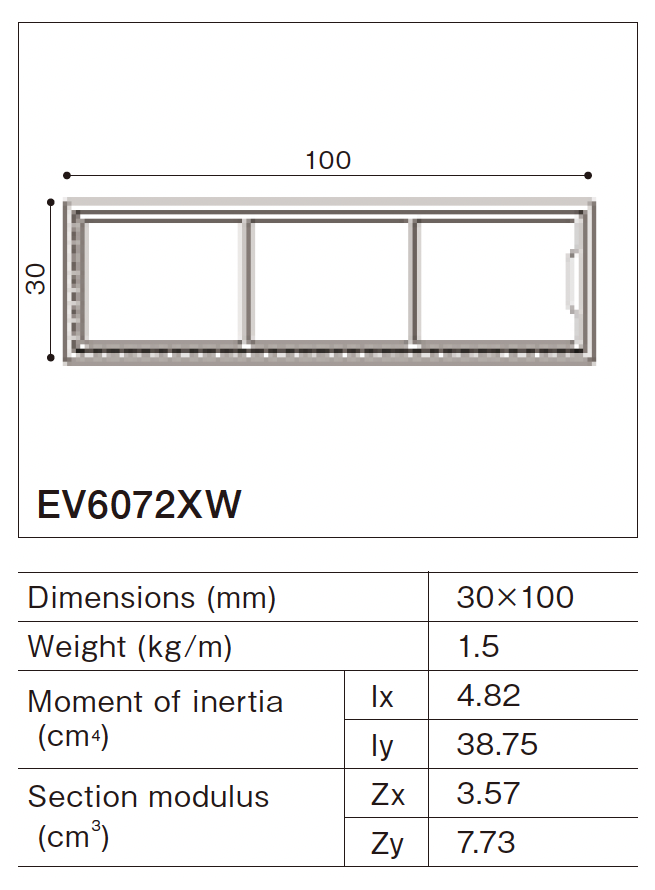

30x100(mm)

87x87(mm)

52.6x52.6(mm)

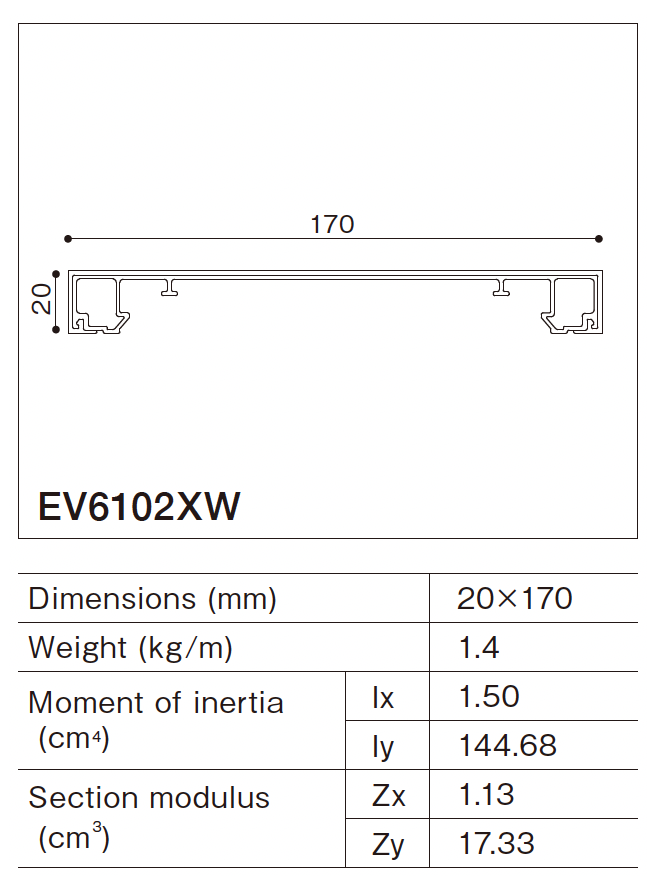

170×20(mm)

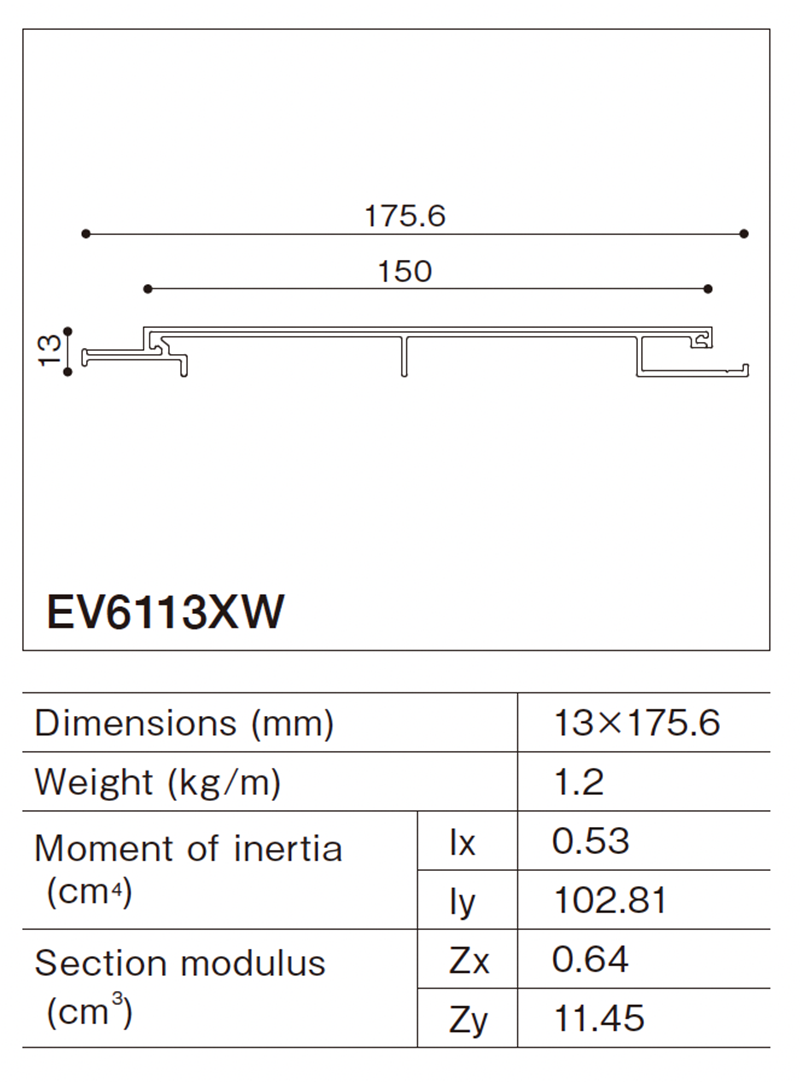

180×20(㎜)

Spandrel

Depending on the design conditions, it may be possible to bend some cross sections without the belt or flange mark. Please inquire for more information.

- Color variations

-

-

Brown

Brown

-

Light Brown

Light Brown

-

Dark Brown

Dark Brown

-

Sandy Brown

(custom order)Sandy Brown(custom order)

-

White

(custom order)White(custom order)

-

※Colors may vary slightly from printed material. Please refer to color samples for accurate colors.

- Options

-

-

・Endcap

An endcap can be glued and fixed to cut sections to improve the aesthetic appeal of the product.

The endcap is made of the same material as the surface resin. -

・Finishing

After the endcap is glued and fixed, additional sanding is used to achieve a finer quality finish with a more integral feel.

-