Case studies

CASE.1Installation of Compact Pavement Inspection System PG-4

Customer name : Nanbara Co., Ltd.

We will provide fast and labor-saving inspection work.

| Product / Device name | Compact Pavement Inspection SystemProduct Details |

|---|---|

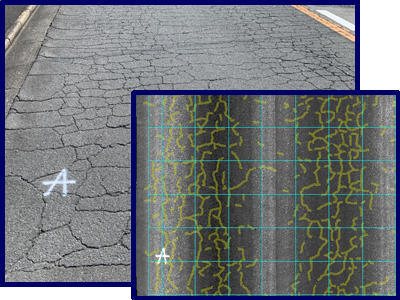

| Purpose | Effectively measure road surface degradation |

Answerer

Mr. Kentaro Kuriya / General manager

Mr.Naoki Iwasaki / Measurement department

Nanbara group is the company having policy ‘Think・Safe・Arrangement’. We made an interview to hear about benefits and other things of PG-4 which was installed to strengthen measurement and inspection work conducted in Nagasaki, Fukuoka and Saga.

Issues before installation of PG-4

- Workload for investigation on sites and making report with human hands

- In order to manage long distance route, we often had to go to sites for investigation with human eyes and for making reports with human hands. Data collection for cracks, ruts and smoothness with human hands took long time to complete the work.

- For rut measurement, we used to measure the survey point with transversal profile meter. It was tough to set up the equipment at every survey point because we had to carry and set up the equipment to the next point manually.

- To trace cracks exactly in the inspection area, Long time was necessary to make sketches at every 10m with human hands after setting up the survey points manually, which was too much work for us.

- Work inefficiency

There was concern to ambient environment including traffic jam and securing the safety since traffic regulation was necessary at every investigation on site.

Benefits after installation of PG-4

- Improvement of work efficiency

- Compared to investigation on sites with human eyes, the cost was reduced by around 75.99% since the working hours also was reduced significantly with high speed moving by the vehicle and automatic data collection. It also contributed to reduce the cost for investigation on sites.

- PG-4 enabled us to collect the data for cracks, ruts and smoothness within PC automatically, which brought us work efficiency.

- As mentioned in the above table, information of cracks, ruts and smoothness acquired by PG-4 eased workload of staff with using analysis software compared to measurement with human hands. Furthermore, PG-4 can be incorporated to overlay system because it provides height information for pavement, and we use the information for longitudinal and transversal plan.

- Controlling traffic regulation and securing safety

Since traffic regulation is unnecessary, it enables improvement of work efficiency and controlling traffic jam.

Based on the factors described in the above, we successfully registered with NETIS. (*)

QS-190035-A

(*)Data base for cutting-edge technology operated by Ministry of Land, Infrastructure, Transport and Tourism

Register No: QS-190035-A