Case Studies

Example for BluePrint company

-

Scanning & copying in service bureau.

-

Tanaka BluePrint Co. Ltd. provides various types of copying and print services.

Main customers are Railway companies and Government offices who need to reproduce drawings or scan and digitize book originals.

Some railway drawings are as long as 20m to 30m.

Tanaka BluePrint is equipped with the latest digital scanners and copiers in order to cope with increasing and more demanding digitizing jobs.

Usage and Benefit of the Flatbed scanner

-

Large book original scanning

Benefiting from the scanner’s large depth of field, the flatbed scanner is being

used to scan “uneven surface documents” such as bound books and Japanese

“Washi” paper. Also it is used to scan fragile documents which need to be handled

with care. When the original is larger than A1 size, Kurabo’s Aupier-GigaLay software is used with the scanner to stitch the divided img. -

2 flatbed scanners are working full time in the Print office

Improving the productivity of book scanning using both monochrome and color scanners.

-

Utilizing the existing scanner and copier in conjunction with the Kurabo software

Aupier-Copy and KB-COPY enables the scanner to send scanned img directly to the existing copiers.

Example for Printing company

Inspection and plate check in printing process.

-

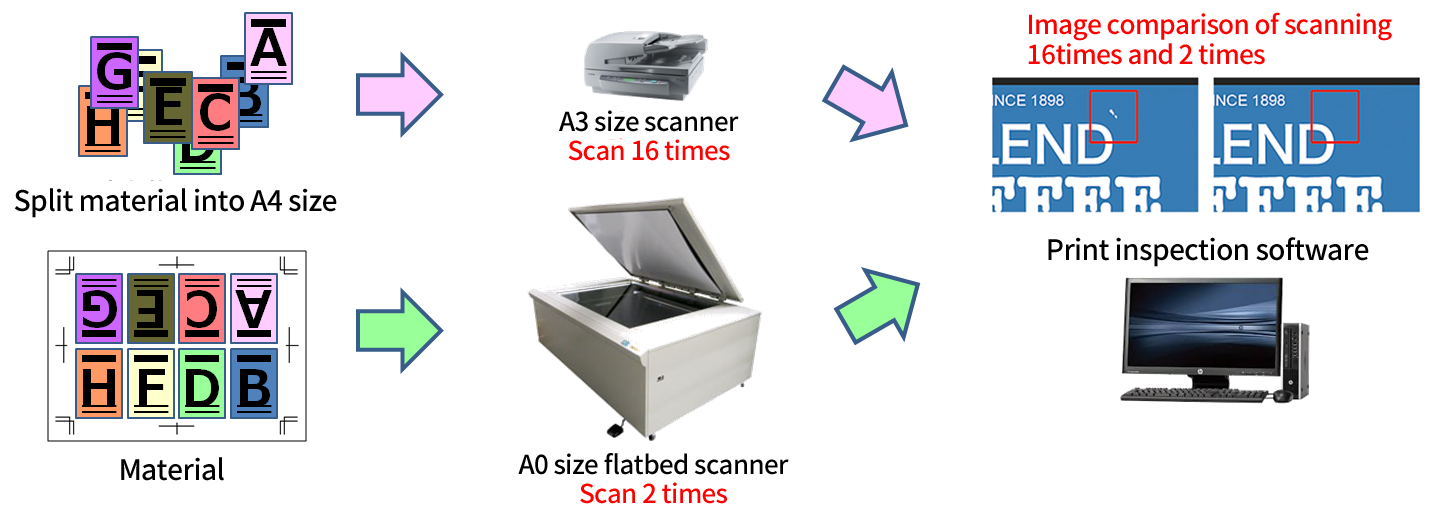

As print production is digitized, high quality requirements from customers are getting higher. Therefore, quality control is very important. However, the inspection process increases, so delivery times and costs increase. A company introduced a A0 size Flatbed scanner and it is possible to drastically reduce the time spent on inspection. In the inspection process so far, they scanned printed samples with an A3 size scanner,

compared the image data with the original digital data, and inspected for dirt and blur. Up to now, A0 size size double-sided printed materials were cut into A4 size, 8 documents were scanned on both sides (total of 16 scans), and comparisons were made 16 times. This time, they introduced the A0 flatbed scanner, drastically improved work productivity by doing two scans (front and back) and two comparisons without separating printed materials.

Example for Construction campany

Digitization of double fold binding in the Construction Industry.

-

Double fold binding (gatefold) is widely used in the construction industry. It is often used on the construction site because it can be folded in two and opened at 180 degrees spread.

In most cases, bound books are handed over to the management company when construction is completed. With one construction, architecture books are over 1000 pages. In addition, its size is mostly large drawings of A0, A1 and A2.

In past architectural books, many blueprints are documented, and deterioration during storage is a serious problem. Part of the Construction Contractors Law in Japan was amended in 2008. As a result, construction companies were obliged to preserve books for 10 years.

Introduction effects.

-

A construction company kept the construction drawing and completed drawings without arranging them in the warehouse. Furthermore, the blueprints was getting worse, the line could not be seen, and the surroundings were yellow.

Introducing Flatbed scanners, they started digitizing drawings and managing them. And they were able to respond immediately to a sudden inquiry from the customer. In addition, outsourcing costs could be greatly reduced by self-manufacture scanning from outsourcing.

Example for the Library in University

Digitization and database compilation of building materials and drawings.

-

About 110 years have passed since the foundation of the university, and during that time they have been trying to improve the campus. Likewise, buildings in the campus have also been expanded and renovated. Some buildings fall under the registered cultural properties. As a research theme to clarify the transition of buildings, including already demolished buildings, we introduced a flatbed scanner to digitize stored design drawings and historical materials. Most of the design drawings are kept in the blueprints and stored, and the deterioration is getting advanced. Digitizing is an important role of preserving historical materials of the university. Scanned drawings are registered in the database including related materials and img and can be viewed. They also publish booklets not only to keep records of research, but also to provide students, graduates, and general people widely.

Example for Nishijin Textile Industrial Association

-

Nishijin Textile Industrial Association is established in 1934 in order to preserve the historical artwork of “Nishijin Textile”. “Mon” can be described as “blueprint for the textile” and once the design is created, it is enlarged and copied to the “Keigami”, a type of grid sheet template, separated by colors.

It requires special skills and patience as the structure of the finished goods, such as ties, kimono belt and fabrics, are all different. We asked the vice president of the association how the Kurabo flatbed scanner is used in the process of digitizing “Mon”

Planning and making “Mon”

-

The Nishijin style of weaving uses yarn dyeing, in which yarns of various colors are woven to make patterns.

This work used to be undertaken by experienced specialists and all done by hand. While preserving its traditional skills, however power looms are now widely used for this process.

Yarn dyeing consists of many steps and they are divided into “Planning and making Mon”, “Preparation of materials”, “Preparation of power loom” and “Weaving”. The Kurabo flatbed scanner is used in the process of “Planning and making Mon”.

-

Mon is created with careful planning of the density of warp and woof, and the design of the textile.

-

The Mon is scanned by flatbed scanner to digitize the design. Sharp, high definition img with fast speed scanning, without damaging the precious original!

-

If the Mon is oversized, it is scanned into multiple sections and Aupier-GigaLay software stitches the divided img. Mon design software then sets the Square pitch template and create the color data using the function of “color separation”

-

The Mon design will be processed into computer graphic data by “Aupier–GigaLay” software by Kurabo and will be sent to the Jacquard loom software.

-

Mon is created with careful planning of the density of warp and woof, and the design of the textile.

Please click HERE to contact us.