Products

Machine Vision

Beverage Can Whole Surface Inspection

Detects dirt and printing leading to complaints about quality,

as well as functional defects such as deformation leading to liquid leakage.

Features

Inner / outer sidewall / bottom / end / flange inspection

We have installed our can whole surface inspection system at many companies, including can manufacturers, beverage makers, and bottlers. We can provide inspection systems to meet the customers’ particular requirements.

The best inspection method to deal with the specific characteristics of can materials.

While conventional can whole surface inspection systems cannot avoid a number of false alarms, KURABO’s system with sophisticated software that is able to identify the specific characteristics of can materials reduces the false alarm ratio to 0.01%.

How it works

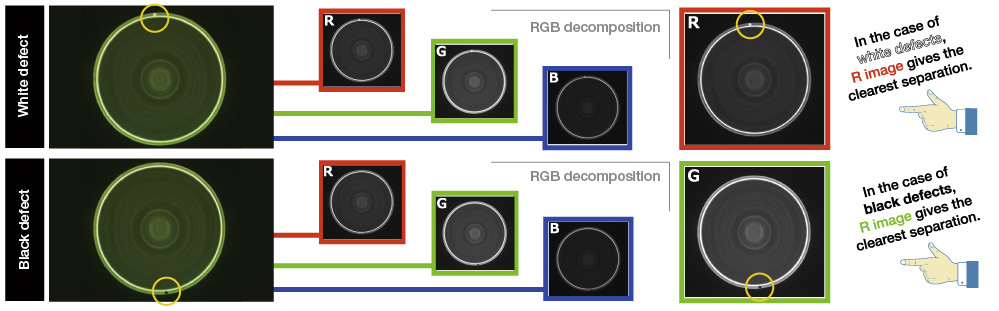

Each defect has its own characteristics in the color image and requires special lighting for detection avoiding false alarms.

KURABO’s sophisticated image processing and lighting technology enables a single inspection system to detect different defects.

Moreover, a threshold can be set for each defect and our customer can expect both good production yields and fewer false alarms.

Inner surface inspection system specifications

| Item | Details |

| Applicable products | Can (DI cans / bottle cans), ends |

|---|---|

| Performance | 2,400cpm (Conveyer) 750cpm (Index) |

| Inspection items | Dirt, foreign matter, missing print, blurring, deformation, crack, chip, etc. |

| Inspection elements | Flange, inner / outer side surface, inner / outer bottom surface, inner / outer end surface |