KK Series

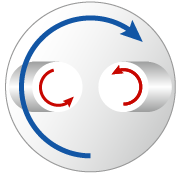

2 axis

Revolution / Rotation independent change

1 axis

Fixed ratio of Revolution / Rotation

Major Features

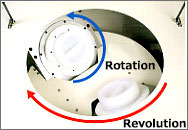

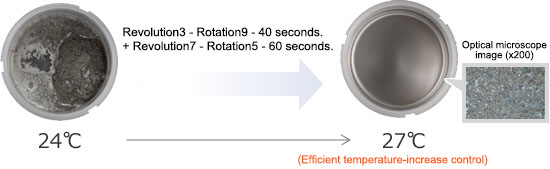

By rotating the container containing the material while orbiting it, mixing and defoaming are performed simultaneously in a short time without using a stirring rod or vacuum equipment. The ratio of rotation and revolution can be changed to set the optimum mixing and defoaming for materials with large differences in specific gravity.

MAZERUSTAR can show you a great performance for the following materials and purposes.

- High viscosity liquids that cannot be handled by conventional equipment, or that take a long time to process.

- Liquids or liquids with powders or fillers which has a large difference of specific gravity.

- Materials required to be processed without waste and contamination. Processes that require less cleaning of equipment and containers.

MAZERUSTAR has 2 unique mechanisms to provide the best performance.

Point 1.

Independently variable revolution /rotation speed ratio (except for some models).

Point 2.

Variable motion continuous step mechanism (up to 5 steps).

Major Applications

MAZERUSTAR is often used in the following applications.

- High viscosity liquids that cannot be handled by conventional equipment, or that take a long time to process.

- Liquids or liquids with powders or fillers which has a large difference of specific gravity.

- Materials required to be processed without waste and contamination. Processes that require less cleaning of equipment and containers.

| Model | KK-250S KK-250SE |

KK-300SS KK-300SSE |

KK-400W KK-400WE |

|---|---|---|---|

| Standard Container(*1) | HDPE 250mL Standard Container |

HDPE 300mL Standard Container |

HDPE 370mL Standard Container |

| Maximum Processing Amount(*2) | 250gx1 container | 310gx1 container | 400gx2 container |

| Revolution | 10 level variable (10-1) | 10 rpm (Fixed ratio of rotation / revolution) *Mixing, medium, degassing, and wave mode are selectable |

10 level variable (10-1) |

| Rotation | 10 level variable(9-0) (0.0-1.0 times of revolution speed) |

10 level variable(9-0) (0.0-0.91 times of revolution speed) |

|

| Setting Time | 10-990 seconds × 5 steps *Max. total operation time: 990 seconds (Units od 10 sec.) *Max. operation time: 990 seconds |

0 second - 30 minutes × 9 steps *Max total operation time: 30 minutes |

10-990 seconds × 5 steps *Max. total operation time: 990 seconds (Units od 10 sec.) *Max. operation time: 990 seconds |

| Channels | 100(Fixed Channels:10、 User Setting Channels:90) |

User Setting Channels:10 | 100(Fixed Channels:10、 User Setting Channels:90) |

| Alarm Function | Unbalance, Top cover and maintenance cover open, Overload | ||

| Safety Function | Automatic stop when error occurs, Door lock during operation, Operation prohibited when the top cover is opened | ||

| Temperature and Himidity for use | 10~40℃、20~80%RH(No dew condensation) | ||

| Power Supply | (S)AC100V±10% (SE)AC200~240V |

(SS)AC100V±10% (SSE)AC200~240V |

(W)AC100V±10% (WE)AC200~240V |

| Power Consumption | Approx.650W | Approx.400W | Approx.750W |

| Monitoring Function (*3) |

○ | - | ○ |

| Dimension (WxDxH) |

350x420x415 mm | 340x315x370 mm | 400x513x457 mm |

| Main Body Weight | 37㎏ | 24㎏ | 51㎏ |

| Model | KK-1000WE | KK-2000WE | KK-5000W KK-5000WE |

|---|---|---|---|

| Standard Container(*1) | HDPE 1.1L Standard Container |

Max. Approx.2L (customer's designated containers are available with adapter) |

HDPE 3.5L Standard Container |

| Maximum Processing Amount(*2) | 1㎏x2 container | 2㎏x2 container | 5㎏x2 container |

| Revolution | 10 level variable (10-1) | 9 level variable(9-1) | |

| Rotation | 10 level variable(9-0) 0.0-0.94 times of revolution speed |

10 level variable(9-0) 0.0-1.0 times of revolution speed |

|

| Setting Time | 0 second - 990 seconds × 5 steps *Max. operation time: 990 seconds |

10-900 seconds × 5 steps *Max total operation time: 25 minutes |

10-300 seconds *Max total operation time: 25 minutes |

| Channels | 100(Fixed Channels:10、User Setting Channels:90) | ||

| Alarm Function | Unbalance, Top cover and maintenance cover open, Overload | ||

| Safety Function | Automatic stop when error occurs, Door lock during operation, Operation prohibited when the top cover is opened | ||

| Temperature and Himidity for use | 10~40℃、20~80%RH(No dew condensation) | ||

| Power Supply | 1φ、AC200V±10% | 3φ、AC200V±5% | (W)3φ、AC200V~240V (WE)3φ、AC380~415V |

| Power Consumption | Approx.2kW | Approx.2.5kW | Approx.7kW |

| Monitoring Function (*3) |

○ | ○ | ○ |

| Dimension (WxDxH) |

565x597x700 mm | 646x663x851 mm | 790x910x1091 mm |

| Main Body Weight | Approx.140kg | Approx.225㎏ | Approx.475㎏ |

| Model | KK-10000 |

|---|---|

| Standard Container(*1) | HDPE 4L Standard Container |

| Maximum Processing Amount(*2) | 10㎏x2 container |

| Revolution | 9 level variable(9-1) (Fixed ratio of rotation / revolution) |

| Rotation | |

| Setting Time | 10-300 seconds × 3 steps |

| Channels | 20(Fixed Channels:10、User Setting Channels:10) |

| Alarm Function | Unbalance, Top cover and maintenance cover open, Overload |

| Safety Function | Automatic stop when error occurs, Door lock during operation, Operation prohibited when the top cover is opened |

| Temperature and Himidity for use | 10~40℃、20~80%RH(No dew condensation) |

| Power Supply | 3φ、AC200V±5% |

| Power Consumption | Approx.10kW |

| Monitoring Function (*3) |

- |

| Dimension (WxDxH) |

950x1070x1224 mm |

| Main Body Weight | Approx.600㎏ |

* Specifications may change without prior notice

(*1)Multiple containers and syringes can be used with an adapter (optional).

(*2)Gross weight including container and adapter. Processing weight may be less depending on operating conditions and the nature of the sample.

(*3)Temperature sensor unit is optional.