Features of MAZERUSTAR

Features of MAZERUSTAR

MAZERUSTAR can mix and defoam at the same time!

MAZERUSTAR is suitable for a variety of materials.

Over the years, we have continued to develop and improve our products to meet the challenges and market needs of our users, and MAZERUSTAR has now grown to become general-purpose machines and even essential products for a wide range of industries, especially for reserch and development.

Client's problems

- check_boxBubbles are adversely affecting product quality.

- check_boxThe material composition is changed by using vacuum equipment.

- check_boxMixing materials with different properties are difficult.

- check_boxHigh viscous material is difficult to handle.

- check_boxRoll mill and blade mixer may damage the particle shape of material.

- check_boxCleaning of containers and equipment is troublesome.

- check_boxThe quality of the material varies greatly from person to person.

- check_boxMixing process is time consuming.

- check_boxMax. processing amount is too small.

Solution

- check_boxCentrifugal force + rotation adjustment can defoam the material without a vacuum equipment.

- check_boxUniform mixing of multiple materials of different specific gravity and viscosity is possible by adjusting the speed balance between revolution and rotation.

- check_boxEven high viscosity of several hundred thousand mPa-s level is possible to mix by combining multiple vectors of strong G (gravitational acceleration) generated continuously.

- check_boxParticle shape is maintained by non-contact method.

- check_boxProcessing inside the container (sealed container), no cleaning is required.

- check_boxProcessing can be done in a short time and at a fixed time without individual differences, making it easy to set up a production schedule.

What is planetary centrifugal mixer?

Revolution for mixing and deaerating

By rotating the container containing the material while orbiting it, mixing and defoaming are performed simultaneously in a short time without using a stirring rod or vacuum equipment.

2 unique mechanisms of MAZERUSTAR

MAZERUSTAR has 2 unique mechanisms to provide the best performance.

Point 1.

Independently variable revolution /rotation speed ratio (except for some models).

Point 2.

Variable motion continuous step mechanism (up to 5 steps).

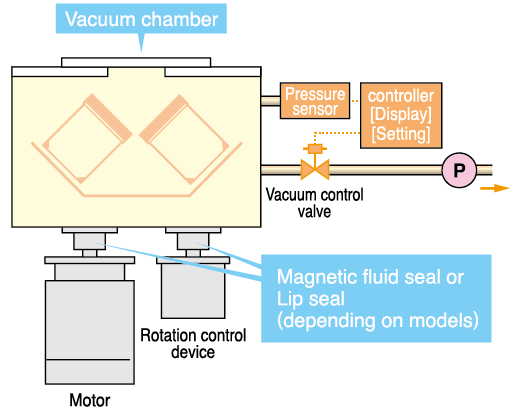

Vacuum equipment model is also available as a lineup of MAZERUSTAR.

A high-performance vacuum pump is used to provide ample vacuum decompression capacity. In addition, the use of a magnetic fluidic seal developed by NASA minimizes the burden on the equipment due to vacuuming and achieves a durability equivalent to that of conventional machines.

Vacuum mechanism

High effective vacuum

Reliable vacuum control

Safety design of motor and electrical systems

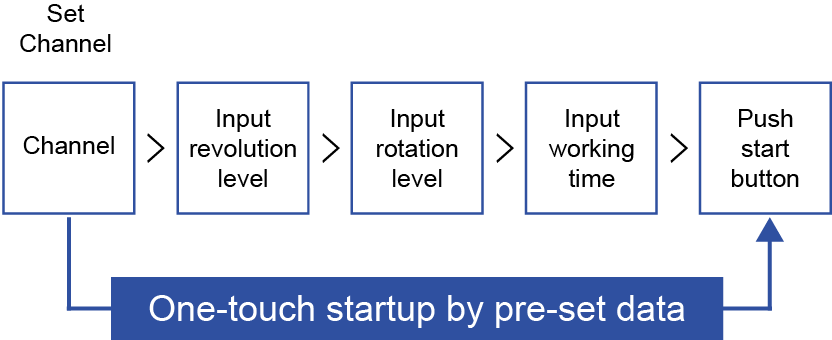

It is simple to operate MAZERUSTAR.

Easy setting with a

simple operation panel

Channel Step Revolution level Rotation level

Target vacuum level

Operation panel of KK-V350W