KKV Series

2 axis

Revolution / Rotation independent change

1 axis

Fixed ratio of Revolution / Rotation

Major Features

Twist

[2-cup eccentric system]・・・KK-V350W (option)

Increased contact surface and friction speed between the material and the inner wall of the container increases mixing and dispersion power.

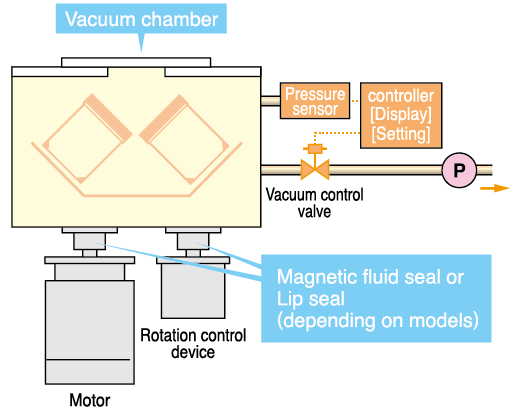

Various vacuum setting parameters

The vacuum can be controlled by monitoring the degree of depressurization, contributing to improved quality control through highly reproducible vacuum control, and providing an optimal defoaming process for various materials.

Ample vacuum decompression capacity

High-performance vacuum pumps are used to achieve a vacuum attainment of 100 Pa and a high-speed vacuum attainment of 2 minutes to 100 Pa.

Reliable Vacuum Control

A magnetic fluidic seal developed by NASA minimizes the burden on the equipment due to vacuuming and achieves a durability equivalent to that of conventional machines.

Vacuum mechanism

High effective vacuum

Reliable vacuum control

Safety design of motor and electrical systems

| Model | KK-V300SS(TYPE-Ⅰ) | KK-V300SS(TYPE-Ⅱ) | |

|---|---|---|---|

| Standard Container(*1) | HDPE 300mL Standard Container | ||

| Maximum Processing Amount(*2) | 310g×1 container | ||

| Revolution | 9 levels (9-1) | ||

| Rotation | 0.5 times of revolution speed | 1.0 times of revolution speed | |

| Setting Time | 10-300 seconds × 5 steps *Max total operation time: 25 minutes |

||

| Number of Channel | 100 (fixed channel: 10, user setting channel: 90) |

||

| Vacuum System | Pump | Ultimate pressure: 200Pa Pumping speed: 133L/160L/ min (50/60Hz) |

|

| Chamber | Independent chamber with reduced pressure only in the vessel rotation area | ||

| Settings | Set vacuum degree kPa voluntarily for each step | ||

| Alarm Function | Unbalance, Upper lid and /or maintenance cover open, and overload | ||

| Safety Function | Automatic shutoff in case any error, locking the door while operation and preventing the system from while the door open | ||

| Temperature and Humidity for use | 10-40℃, 20-80%RH (No dew condensation) | ||

| Power Supply | AC100V±10% | ||

| Power Consumption | Approx.1.5kW | ||

| Monitoring Function (*3) |

○ | ||

| Dimension | 685×602×490 mm | ||

| Main Body Weight | Approx.103kg | ||

| Model | KK-V350WE | |

|---|---|---|

| Standard Container(*1) | HDPE 370mL Standard Container | |

| Maximum Processing Amount(*2) | 350g×2 containers | |

| Revolution | 9 levels (9-1) | |

| Rotation | 10 levels (9-0) (0.0-1.0 times of revolution speed) |

|

| Setting Time | 10-300 seconds × 5 steps *Max total operation time: 25 minutes |

|

| Number of Channel | 100 (fixed channel: 10, user setting channel: 90) |

|

| Vacuum System | Pump | Ultimate pressure: 100Pa Pumping speed: 100L/120L/ min (50/60Hz) |

| Chamber | Independent chamber with reduced pressure only in the vessel rotation area | |

| Settings | Set vacuum degree kPa voluntarily for each step | |

| Alarm Function | Unbalance, Upper lid and /or maintenance cover open, and overload | |

| Safety Function | Automatic shutoff in case any error, locking the door while operation and preventing the system from while the door open | |

| Temperature and Humidity for use | 10-40℃, 20-80%RH (No dew condensation) | |

| Power Supply | AC200~240V | |

| Power Consumption | Approx.2.0kW | |

| Monitoring Function (*3) |

○ | |

| Dimension | 565×682×725 mm | |

| Main Body Weight | Approx.160kg(vacuum pump is not included) | |

| Model | KK-V1000W | |

|---|---|---|

| Standard Container(*1) | HDPE 1.1L Standard Container | |

| Maximum Processing Amount(*2) | 1kg × 2 containers | |

| Revolution | 9 levels (9-1) | |

| Rotation | 10 levels (9-0) (0.0-0.94 times of revolution speed) (Limited by the level of revolution) |

|

| Setting Time | 10-300 seconds × 5 steps(*3) | |

| Number of Channel | 100 (fixed channel: 10, user setting channel: 90) |

|

| Vacuum System | Pump | Ultimate pressure: 6.7Pa Pumping speed: 200L/240L/ min (50/60Hz) |

| Chamber | Independent chamber with reduced pressure only in the vessel rotation area | |

| Settings | Set vacuum degree kPa voluntarily for each step | |

| Alarm Function | Unbalance, Upper lid and /or maintenance cover open, and overload | |

| Safety Function | Automatic shutoff in case any error, locking the door while operation and preventing the system from while the door open | |

| Temperature and Humidity for use | 10-40℃, 20-80%RH (No dew condensation) | |

| Power Supply | 3φ、AC200V±10% | |

| Power Consumption | Approx.3.0kW | |

| Monitoring Function (*3) |

○ | |

| Dimension | 761×784×822 mm | |

| Main Body Weight | Approx.260kg(vacuum pump is not included) | |

| Model | KK-V3500 | |

|---|---|---|

| Standard Container(*1) | HDPE 3.5L Standard Container | |

| Maximum Processing Amount(*2) | 3.5kg×2 containers | |

| Revolution | 9 levels (9-1) | |

| Rotation | 10 levels (9-0) (0.0-0.78 times of revolution speed) (Limited by the level of revolution) |

|

| Setting Time | 10-300 seconds × 3 steps | |

| Number of Channel | 20 (fixed channel: 10, user setting channel:10) |

|

| Vacuum System | Pump | Ultimate pressure: 20Pa Pumping speed: 49㎥/h(50Hz)、59㎥/h(60Hz) |

| Chamber | Independent chamber with reduced pressure only in the vessel rotation area | |

| Settings | 3 mode settings 1: Keep vacuum level 1 2: Keep vacuum level 2 3: Continuous vacuum |

|

| Alarm Function | Unbalance, Upper lid and /or maintenance cover open, and overload | |

| Safety Function | Automatic shutoff in case any error, locking the door while operation and preventing the system from while the door open | |

| Temperature and Humidity for use | 10-40℃, 20-80%RH (No dew condensation) | |

| Power Supply | 3φ、AC200V±10% | |

| Power Consumption | Approx.7.0kW | |

| Monitoring Function (*3) |

- | |

| Dimension | 1095×995×1150 mm | |

| Main Body Weight | Approx.550kg(vacuum pump is not included) | |

* Specifications may change without prior notice.

(*1)Multiple types of containers and syringes can be used by optional adapters.

(*2)Gross weight including container and adapter. Processing weight may be less depending on operating conditions and sample characteristics.

(*3)Temperature sensor unit is sold separately.