MAZERUSTAR Application Field

MAZERUSTAR provides you

the solutions with automation system

Based on the know-how of "powder weighing" and "liquid weighing", we propose the automation system of material preparation process with robots.

Please feel free to contact us.

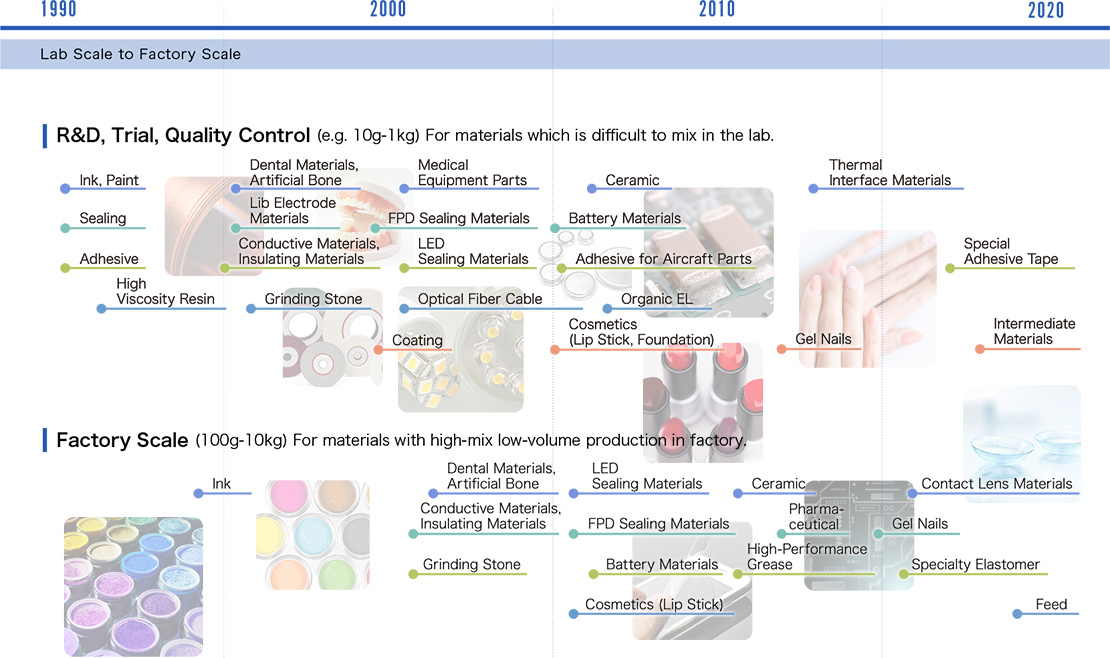

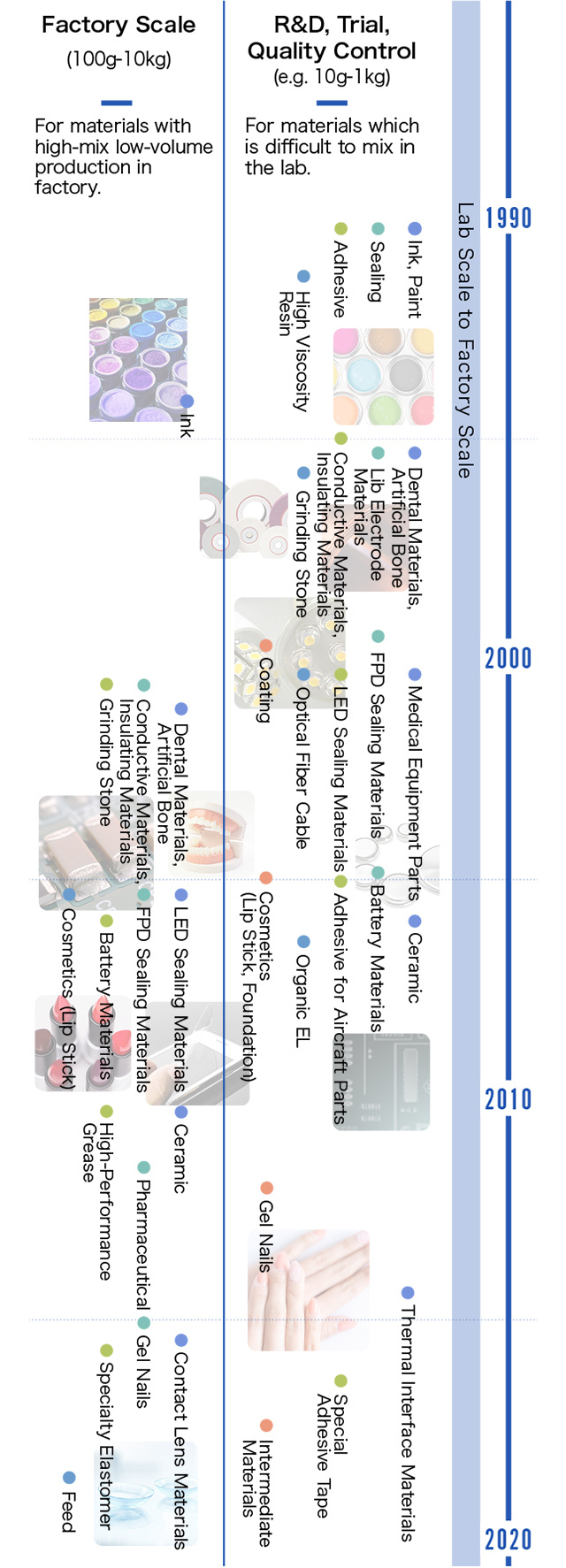

MAZERUSTAR is used in a variety of industries.

MAZERUSTAR contributes a wide range of industries such as electronics, chemical, medical, cosmetics, automotive, and aircraft industries.

-

Chemicals

- Adhesive

- Ink, Paint, and Pigment

- Rubber Products

- Resin

- Grease

- Insulating Oil

- Heavy Oil

Electronics

- Conductive Materials, Silver Pastes

- Copper Pastes, Gold Pastes

- Resistance, Capacitor Materials

- Resist Ink

- Molding Materials

- Insulating Materials

- Battery Materials

Medical and Cosmetic

- Dental Materials

- Artificial Bone

- Ointment

- Medical Equipment Parts

- Lip Stick, Foundation, and Nails

- Contact Lens Materials

Automotive and Aircraft

- Adhesive

- Ceramic

- Thermal Interface Materials

- LED

Aircraft

- Adhesive

Others

- Grinding Stone

- Glass

- Ceramic

- Food-related Materials

MAZERUSTAR Lineup

Select your model based on the amount of throughput and application.

Click for more details

| Processing Amount | KK Series (Standard model) |

KKV Series (Vacuum type model) |

|---|---|---|

| 250g×1Cup | ||

| 310g×1Cup | ||

| 350g×2Cup | ||

| 400g×2Cup | ||

| 1kg×2Cup | ||

| 2kg×2Cup | ||

| 3.5kg×2Cup | ||

| 5kg×2Cup | ||

| 10kg×2Cup |

Containers and Adapters

In addition to standard containers, containers such as disposable cups and customized cups are available by using an adapter (option).

Especially for syringes, adapters for setting multiple syringes are available to efficient your production.

(Patent: 3421745)

Automated Dispensing System

Automated dispensing system for powder, liquid, and resin. KURABO Automated Dispensing System improves accuracy of dispensing and saves processing time. The tank can be designed freely as a unit, and it is easy to change the materials.

Option

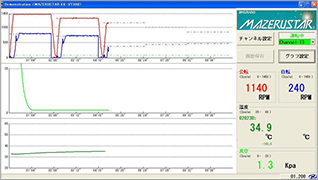

We provide PC communication software and temperature measurement unit for MAZERUSTAR.

Software for MAZERUSTAR

RPM is displayed on the PC screen in real time during operation. Operation data such as operation time, rotation speed, vacuum, temperature, etc. can be saved and checked later.

Problems

- check_boxOperating conditions cannot be checked after the operation is finished.

- check_boxActual RPM is not shown in real time.

- check_boxThere is a risk to select wrong operating conditions.

- check_boxRegistering each setting is time-consuming.

Solutions

- check_boxOperation data such as operation time, rotation speed, vacuum, temperature, etc. can be saved and checked later.

- check_boxRPMs are displayed on the PC screen in real time during operation.

- check_boxThe barcode reader can be used to set operating conditions, reducing selection errors.

- check_boxThe operating conditions can be edited on the PC.

Supported Models

・KK-250S/KK-250SE・KK-400W/KK-400WE

・KK-1000WE・KK-2000WE

・KK-5000W/KK-5000WE

・KK-V300SS・KK-V350WE・KK-V1000W

Temperature Measurement Unit

By attaching a temperature measuring unit to the container setting location, the temperature at the bottom of the container can be measured in real time and displayed on a PC screen via communication.

Problems

- check_boxThe materials is affected by high temperature, but temperature during the operation cannot be checked.

- check_boxThere is no indicator to check the mixing conditions and results.

Solutions

- check_boxBy attaching a temperature measuring unit to the container setting location, the temperature at the bottom of the container can be measured in real time and displayed on a PC screen via communication.

- check_boxTemperature change during the operation can be the indicator for the mixing results.

Supported Models

・KK-400W/KK-400WE・KK-1000WE

・KK-2000WE・KK-5000W/KK-5000WE

・KK-10000

Case Study

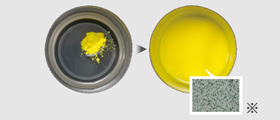

LED Sealing

High shear force enables uniform defoaming

and improved performance.

It meets the needs for agitation

and defoaming in a short period of time.

Lip Stick

Uniform agitation of pearlescent, metallic,

and other powders is also possible.

Adjustment of the revolving

and rotation speeds enables

the machine to handle powders with high specific gravity.

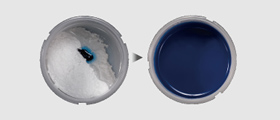

Pharmaceuticals / Medical

Independently variable revolving

and rotation speed mechanisms enables uniform agitation

and deaeration of powder materials

and materials with large differences in specific gravity.

Ceramic Pastes

Ceramic powder tends to sink easily

due to its high specific gravity,

making it difficult to stir evenly.

However, by increasing the rotation speed ratio,

the powder does not sink and can be stirred evenly.

Applications for LIB Electrode

Kanagawa University Report using MAZERUSTAR KK-250S

Outline

In recent years, there has been a demand for an easier and more efficient method of manufacturing lithium-ion batteries (LIBs) due to manufacturing cost issues and other factors.

LIB electrodes are made by mixing cathode or anode active material particles with a conductivity aid and binder with a dispersing solvent, then coating and drying the resulting uniform slurry on a metal current collector.

The mixing process is an important factor in battery reliability because battery performance may not be stable if the dispersion of electrode active material/conductivity aid/binder is not sufficient.

Learn moreMajor Applications

MAZERUSTAR is often used in the following applications.

- Conductive / Resistor material (e.g. gold, silver, and carbon pastes)

- Sealing / Insulating material (e.g. glass and ceramic pastes)

- Adhesive / Sealing material (e.g. one / two-component epoxy resins)

- Molding material (e.g. silicon resins)

- Mixing for coloring material (e.g. ink, paint, and pigment)

- Manufacuturing for dental material, Pharmaceutical material, and cosmetic material

- Grinding for electronics component